Biomedical Engineering Reference

In-Depth Information

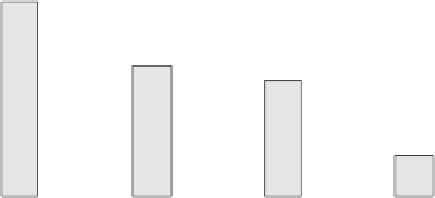

0.02

ball wear (mm

3

)

Flat wear (mm

3

)

0.018

0.016

0.014

0.012

0.01

0.008

0.006

0.004

0.002

0

10.00

175.25

240.50

259.50

Residual Compressive Stress (MPa)

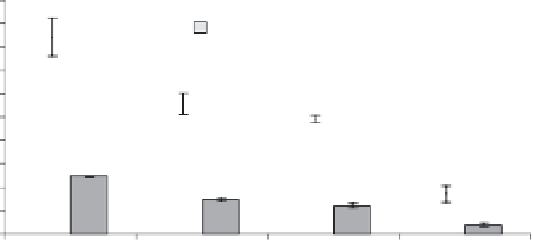

Figure 10.10.

Ball on fl at wear data: alumina ball on alumina fl at showing the clearly

improved wear resistance due to compressive stresses in the surface layer of the fl at. Residual

stresses in fl at measured by XRD.

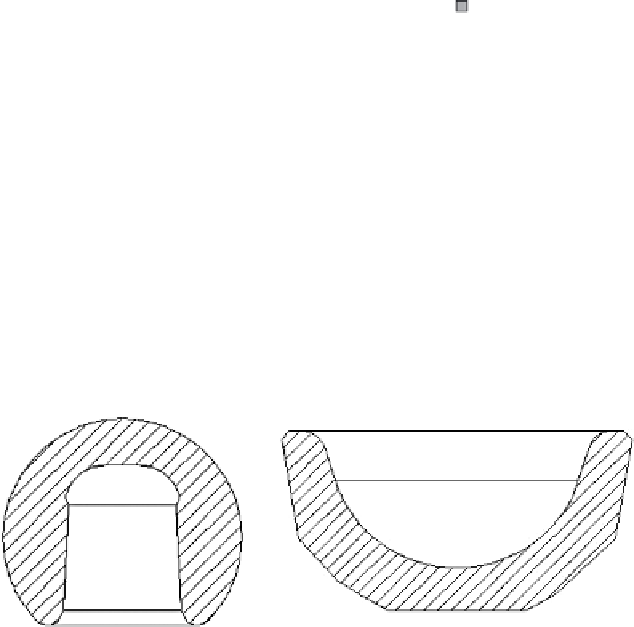

Figure 10.11

Schematic cross-sections of a ball-head with a diameter of 28 mm and a corre-

sponding acetabular cup insert. [Anné, 2005a].

10.6 BALL-HEADS AND CUP INSERTS MADE BY EPD

10.6.1 Introduction

During EPD, the deposit takes the shape imposed by the deposition electrode.

For processing complex shapes, the only shape limitation is the feasibility to

remove the deposit from the electrode after deposition. The deposition electrode

has therefore the shape of the outer surface of the acetabular cup insert and of

the ball-head (Figure 10.11) and consists for the latter of an upper and lower part,

allowing removal of the EPD deposit. Complex geometries like femoral ball-

heads and cup inserts require appropriate design of the counter electrode in order

to generate a constant electric fi eld at the surface of the deposition electrode. The

design of the most suitable counter electrodes needs, therefore, to be supported

by electric fi eld calculations using fi nite element analysis and is discussed in the

next section 10.6.2 .

Search WWH ::

Custom Search