Biomedical Engineering Reference

In-Depth Information

2004]. A review of the coatings commercially available for metal-PE joints has

been given by Piconi et al. (2004).

A procedure often adopted for commercial hip joint implants is to coat parts

of the metallic femoral stem by a porous hydroxyapatite coating in order to

improve the bonding between implant and bone. This is usually done by plasma

spraying; see L. Sun et al. (2001) for a review. Other ceramics and coating methods

are being investigated.

10.3.5 Functionally Graded Ceramics for Hip Components

The concept of functionally graded materials (FGM) originates from the observa-

tion that many components only need to posses a certain property locally while

elsewhere another often irreconcilable property is required by the design. To

increase the strength of ceramic ball-heads, the concept of functionally-graded

materials can be used to develop ceramic Al

2

O

3

/ZrO

2

graded composites. The

potential of this bioinert system follows from the properties of Al

2

O

3

(low wear

rate, high hardness) and ZrO

2

(high strength, high toughness).

Due to the difference in thermal expansion coeffi cient of Al

2

O

3

and ZrO

2

,

residual stresses are developed during cooling from the sintering temperature,

which can strongly infl uence the mechanical properties like strength and tough-

ness. Compressive surface stresses in the outer alumina layer will have a benefi -

cial effect on the wear resistance [Katti, 2004].

The design of the composition gradient has to be in such a way that it gener-

ates compressive stresses at those places that are loaded under tensile stress. To

obtain a benefi cial effect on the strength and tribological properties of the com-

ponent, compressive stresses at the surface of the component have to be gener-

ated. A correct design of the gradient from the point of view of thermal stresses is

therefore of primary importance [Toschi et al., 2003; Gasik et al., 2003].

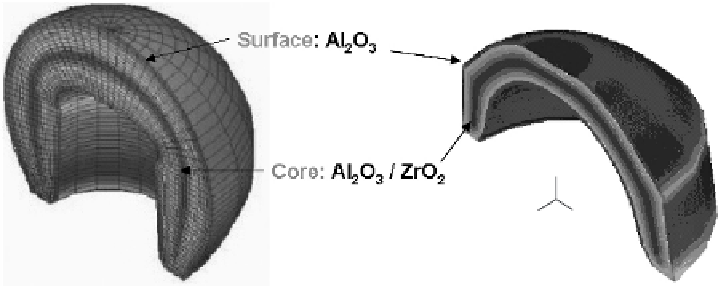

Figure 10.2 shows the concept of FGM ball head, which has been investigated.

Note that all outer surfaces of the ball head as well as the acetabular cup consist of

a mm thick layer of pure alumina. The zirconia is only present in the interior and

is not exposed to the environment so that LTD will not be an issue.

2

3

1

Figure 10.2.

Schematic of an Al

2

O

3

/ZrO

2

FGM ball-head and liner. [Anné, 2005a].

Search WWH ::

Custom Search