Biomedical Engineering Reference

In-Depth Information

(a)

200

μ

m

(b)

20

μ

m

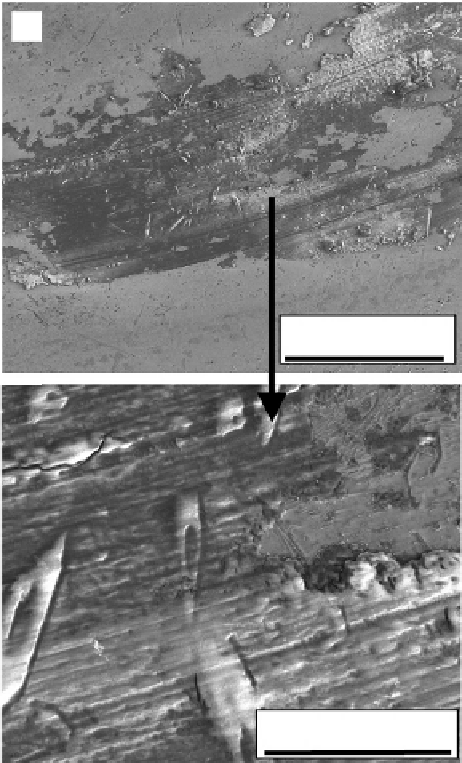

Figure 9.26.

Lower magnifi cation (a) and (b) higher magnifi cation secondary SEM images of

wear tracks on the surface of oxidized TNZT + 2B after friction studies using Si

3

N

4

counterface

balls. [Sonia Samuel et al.

Wear Resistance of Laser Deposited Boride

Reinforced Ti

-

Nb

-

Zr

-

Ta

Alloy Composites for Orthopedic Implants

(to appear in Mater. Sci. Eng. C, 2007)]

titanium oxide layers, like the rutile phase have been shown to be very effective

in lowering the friction coeffi cients (

0.2) and wear rates [45]. This narrowed the

wear tracks with no signifi cant third body debris formation that might result in

severe abrasive wear. Thus the titanium oxide layer acted as a lubricous oxide and

prevented boride particles from being potentially pulled out of the matrix,

and thereby improved the wear resistance considerably for both Ti-6Al-4V ELI

and TNZT + 2B. Lastly, there were no signifi cant differences in the wear track

morphologies between the alloys outside of some patchy regions in TNZT + 2B

that did not contribute to the overall friction behavior.

∼

Search WWH ::

Custom Search