Biomedical Engineering Reference

In-Depth Information

due to the harder and more resistant TiB precipitates. One possible explanation

for this behavior is the pull-out of the harder TiB precipitates from the matrix

resulting in third body wear, which would accelerate abrasive wear events by

ploughing and deep grooving, as shown in Figure 9.23b. The SEM image in Figure

9.23 c confi rms that one of several TiB precipitates (

m on edge) being pulled-

out of the matrix inside the wear track, which is in agreement with previous

observations of boride pull out from the matrix of Ti-6Al-4V reinforced with TiB

2

[41]. From these results, it was surmised that the Si

3

N

4

ball, much harder than

would be active in a hip prosthesis contact where a ultra-high molecular weight

polyethylene (UHMWPE) coated surface is typically the wearing counterface,

was responsible for precipitate pull - out from the Ti - 6Al - 4V matrix. Therefore, the

use of a softer SS 440C counterface against the candidate alloys will be addressed

below.

In order to lower the friction and wear of Ti-6Al-4V ELI and the TNZT + 2B,

the samples were heat treated at 600 °C for ten hours in air to promote the forma-

tion of toughened oxide layers and fi ner

∼

10

μ

precipitates in TNZT + 2B. SEM

images of the oxidized TNZT + 2B surface, not shown, could not resolve the very

small

α

precipitates through the oxide layer. However, after removal of the oxide

layer via mechanical polishing, the fi ne scale

α

precipitates could be resolved

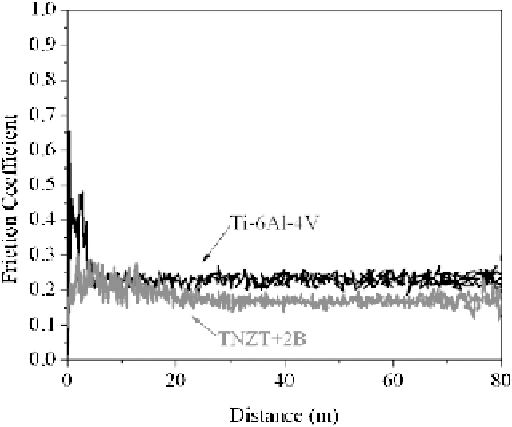

using high resolution SEM imaging. Typical friction coeffi cient curves of the alloys

sliding against Si

3

N

4

, shown in Figure 9.24, are much lower than the non-oxidized

alloys. After an initial run-in period, the steady-state friction coeffi cients are

α

∼

0.23

Figure 9.24.

Wear plots showing the friction behavior as a function of distance of oxidized

surfaces (600 °C/10 hrs) of Ti-6Al-4V ELI and TNZT + 2B with Si

3

N

4

counterface balls. [Sonia

Samuel et al.

Wear Resistance of Laser Deposited Boride Reinforced Ti

-

Nb

-

Zr

-

Ta Alloy

Composites for Orthopedic Implants

(to appear in Mater. Sci. Eng. C, 2007)]

Search WWH ::

Custom Search