Biomedical Engineering Reference

In-Depth Information

Sputtered 0 min

Sputtered 12 min

Sputtered 22 min

Base

TNZT

Nb 3d

Nb

2

O

5

3d5/2

Nb

2

O

5

3d3/2

NbN(1-y)O(y)3d5/2

Nb

2

O

5

3d5/2

NbO

2

3d5/2

100000

NbO0.2/Nb 3d5/2

Nb 3d5/2

Nb

2

O

5

3d3/2

90000

NbO3d5/2

80000

70000

Nb

2

O

5

3d5/2

Nb

2

O

5

3d3/2

60000

50000

40000

30000

20000

Nb 3d5/2

NbO3d5/2

Nb

2

O

5

3d5/2

Nb

2

O

5

3d3/2

220

215

210

205

200

195

BE eV

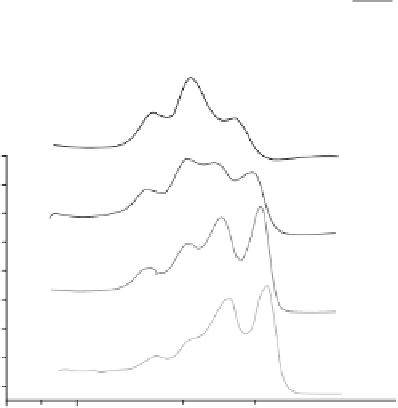

Figure 9.14.

XPS Spectra of Nb3d on the oxide and base TNZT. [Sonia Samuel, (M.S. Thesis,

Dept of Mater. Sci. and Eng., University of North Texas, 2007)]

mixed metal + oxide layer. Figure 9.14 shows the XPS spectra corresponding to

the Nb3d peak after different sputtering time periods of zero, twelve and twenty-

two minutes into the surface oxide layer of the LENS™ deposited TNZT alloy.

The surface of the oxide layer showed the presence of Nb

2

O

5

3d5/2 (E

b

= 207.01 eV)

oxide and an oxy-nitrile of the composition NbN(1-y)O(y) 3d5/2. (E

b

= 203.6 eV).

After sputtering for 12 minutes and beyond into the oxide layer, other types of

niobium oxides are detected including, NbO

2

, NbO0.2Nb and NbO. Metallic Nb

peak appears after sputtering for 22 minutes into the oxide layer. As in the case

of titanium, niobium oxide peaks are detected in the XPS spectra even after a

sputtering of 30 minutes into the oxide layer suggesting the presence of a mixed

metal + oxide layer. In the case of the elements Zr and Ta XPS spectra were col-

lected for conditions similar to those used for Ti and Nb as shown in Figures 9.15

and 9.16. In the case of Zr the oxide present in the surface passive layer was found

to be ZrO

2

and after sputtering for about 22 minutes into the oxide layer, the

peaks corresponding to the metallic Zr was detected, as seen in Figure 9.15. Inter-

estingly in case of Ta, as seen in Figure 9.16, while Ta

2

O

5

was the oxide present in

the surface passive layer, metallic tantalum was also detected even for 0 mins

sputtering. This can be explained based on the fact that since Ta is a much more

noble metal as compared to Ti, Nb, or Zr, there is a substantially reduced ten-

dency for the oxidation of this alloying element in the surface passive layer

forming on the LENS™ deposited TNZT alloy. A summary of the different oxides

detected in the passive oxide layer on the surface, based on the XPS studies, is

shown in Table 9.1 .

Search WWH ::

Custom Search