Biomedical Engineering Reference

In-Depth Information

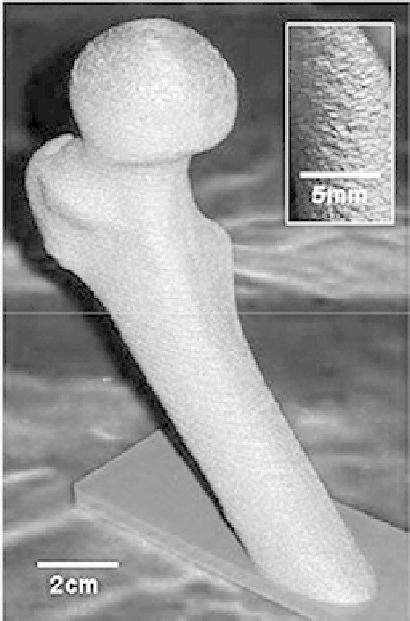

Figure 9.3.

LENS™ deposited hip (femoral) implant with internal cavity. [Optomec Design

Company, Albuquerque, New Mexico, U.S.]

There the two powder feeders along with the laser setup and the visual

monitor is drawn. The actual picture of the LENS equipment is shown in the

bottom part of the fi gure. The LENS™ process has been commercialized by the

company Optomec Inc., based in the United States, and has been demonstrated

to be a viable processing technology for fabrication of orthopedic implants, e.g.,

femoral hip implants. For example, a prototype hollow femoral implant made

from Ti - 6Al - 4V using LENS ™ is shown in Figure 9.3 .

One of the key strength of LENS™ processing is that by using a

powder-feeder system consisting of multiple hoppers, it is possible to process

compositionally-graded and consequently functionally-graded materials. Thus,

by controlling the deposition rates from individual hoppers, it is possible to design

compositionally graded materials as demonstrated in a number of previous

papers on laser - processed compositionally - graded titanium alloys [25 - 26] . From

the viewpoint of orthopedic implants, compositionally-graded alloys can be par-

ticularly benefi cial since they will enable the development of custom-designed

orthopedic implants with site-specifi c properties. Furthermore, engineering func-

Search WWH ::

Custom Search