Biomedical Engineering Reference

In-Depth Information

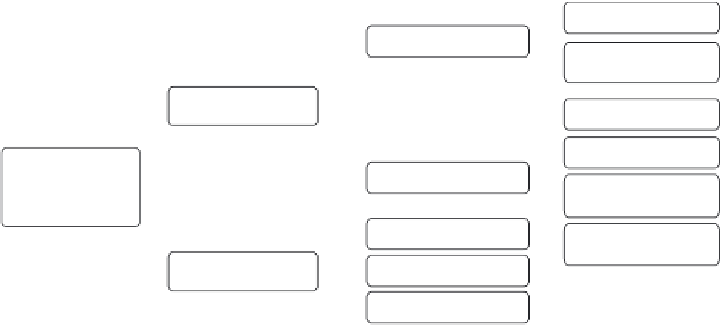

Filament binding

Open mold

Vacuum bag

autoclave

Fiber reinforced

Compression

Injection molding

Composites

processing

Closed mold

Continuous

pultrusion

Hot pressing/Forging

Composite flow

molding

Pre-drawing

Particle reinforced

Miscellaneous

Figure 8.5.

Schematic representation of composite processing techniques.

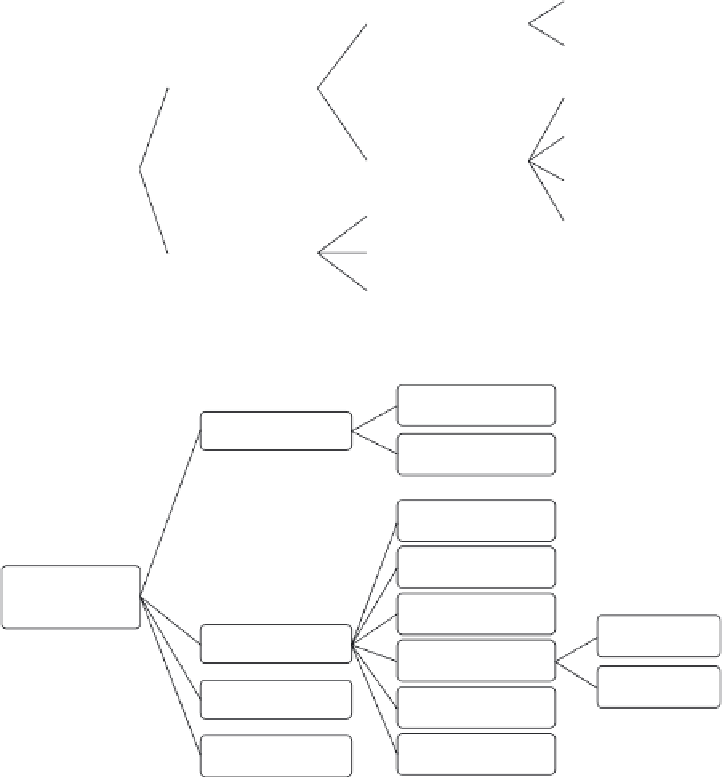

Powder blending

and consolidation

Foil diffusion

bonding

Solid state

Electroplating/

Electroforming

Stir casting

Processing of

MMC

Pressureless

infiltration

Pressure assisted

infiltration

Centrifugal

casting

Squeeze

casting

Liquid state

Vapor deposition

Spray deposition

Reactive

processing

Rapid prototyping-

Lens

®

Figure 8.6.

Schematic representation of processing techniques used for manufacturing

MMCs.

they possess unique manufacturing techniques (Figure 8.6) by virtue of metals

being their continuous phase. Depending on the properties desired in the fi nal

composite, processing can vary from conventional metal processing to advanced

rapid prototyping.

Discontinuous MMC's can be produced with standard metalworking tech-

niques, such as extrusion, forging or rolling as stated in the section 8.3.1.2 on

metals in this chapter. However, functionally graded MMC's [58] (in which the

composition and microstructure change gradually from one side to the other) and

cermets can be manufactured using techniques such as LENS

®

[59]. In addition to

the aforementioned techniques, there are other processing techniques that have

been used for the fabrication of specifi c biocomposites as shown in Table 8.1 .

Search WWH ::

Custom Search