Biomedical Engineering Reference

In-Depth Information

Although the aforementioned steps of processing are commonly applicable

to most polymeric biomaterials, there can be special applications wherein the pro-

cessing of polymers can be relatively unique. One such example is that of process-

ing polymers for the fabrication of scaffolds to be used in tissue engineering

applications. Scaffolds are usually made from biodegradable polymers and act as

a transient ECM that provides support and guidance for the growth of seeded

cells that eventually leads to the formation of new tissue. Hence the polymers

used for the fabrication of scaffolds are necessarily biocompatible and biodegrad-

able while providing mechanical strength (especially important in the case of

hard tissue regeneration) and being intrinsically transient in nature. In addition to

these properties, more recent scaffolding systems are associated with proteins

such as growth factors that govern tissue growth. The association of proteins with

scaffolds limits the processing conditions in terms of temperature and usage of

solvents, thereby making the processing more challenging. Various techniques

that have been previously reported for the fabrication of scaffold are: fi ber

bonding, solvent casting and salt leaching, phase separation, freeze drying, mem-

brane lamination, melt molding, and

in situ

polymerization [46, 47] .

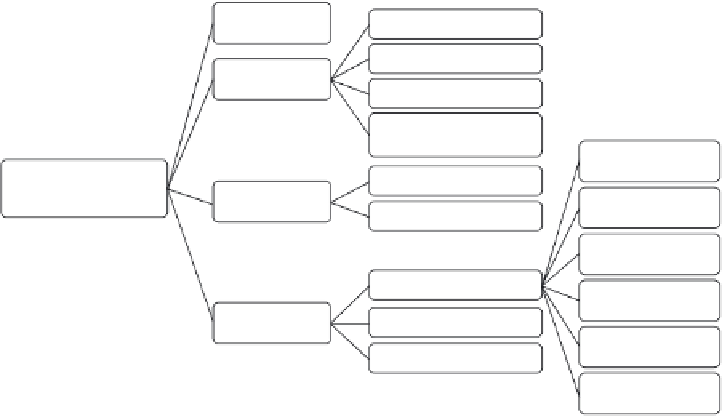

8.3.3.2.2 SURFACE TREATMENT [48] . Polymeric materials also undergo

various surface fi nishing processes (Figure 8.4) with the aim of improvement of

appearance, biocompatibility and biointegration.

Polymers, being chemically and physically versatile, have been used in a

variety of biomedical applications. Due to the versatility of polymers and the

growth in the biomedical device industry, the processing of polymeric biomate-

rials has experienced an exponential growth in the past few decades. Future

development should involve machinery design, process analysis and optimization

to enable the fabrication of polymeric products with improved properties.

Oxidation by

air

Interpenetrating grafts

Cross-linked grafts

Grafting

Brush grafting

Stimuli-responsive

grafts

Embossing

Polymer surface

modifications

Plasma modification

High energy

treatment

Fused deposition

modeling process

Gamma irradiation

Ink jet printing

Contact printing

Microcontact

printing

Proton

micromachining

Surface

printing

Laser etching

E-beam etching

Rapid prototyping

Figure 8.4.

Schematic representation of techniques used for polymer surface modifi cations.

Search WWH ::

Custom Search