Biomedical Engineering Reference

In-Depth Information

traditional PLGA) and ease of degradability, it has been considered as a new

generation of tissue engineering scaffold for numerous tissue engineering com-

posite applications especially for bone and articular cartilage.

7.3.3.2 Nanostructured and Injectable Hydrogels as Bone Tissue Engi-

neering Scaffolds.

Polymeric hydrogels have excellent biocompatibility which

makes them useful in orthopedic applications (such as for injectable bone repair

and cartilage reconstruction) [100]. Natural hydrogels (such as collagen and gela-

tin) are the main components of extra cellular matrices (ECM) of mammalian

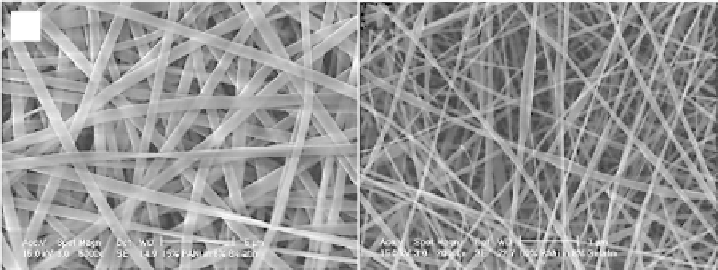

tissues including bone, cartilage, and so on [101]. Through a technique called elec-

trospinning, nanofi brous scaffolds [104] can be successfully created from various

synthetic and natural polymers such as gelatin and collagen (Figure 7.9).

Several studies have shown that protein and cell interactions are promoted

by nanofi brous scaffolds that biomimic the ECM [102-103]. On the other hand,

studies have demonstrated that using self-assembling peptide KLD-12 hydrogels

for encapsulating chondrocytes can support chondrocyte differentiation and

promote the synthesis of a cartilage-like extracellular matrix for cartilage repair

[105] .

In addition, various synthetic hydrogels such as poly(2-hydroxyethyl methac-

rylate) (pHEMA) were modifi ed to have nanofeatures for orthopedic applica-

tions. For example, some studies have created an injectable nanostructured

pHEMA-hydrogel scaffold which incorporates novel self-assembled helical

rosette nanotubes (HRNs) into hydrogels to fi ll bone fractures and repair bone

defects [106]. The nanoscale, tubular architecture of HRNs on and in hydrogels

can provide a topography that improves protein adsorption and an environment

(a)

(b)

Figure 7.9.

Scanning electron microscopy images of electrospun polyaniline-contained

gelatin nanofi bers. (A) polyaniline-gelatin blend fi bers with ratios of 15 : 85 and (B)

polyaniline-gelatin blend fi bers with ratios of 60 : 40. This Fig. shows that the electrospun fi bers

are homogeneous while 60 : 40 fi bers were electrospun with beads [104]. Scale bars = 5

μ

m for

(A) and 1

μ

m for (B).

Search WWH ::

Custom Search