Biomedical Engineering Reference

In-Depth Information

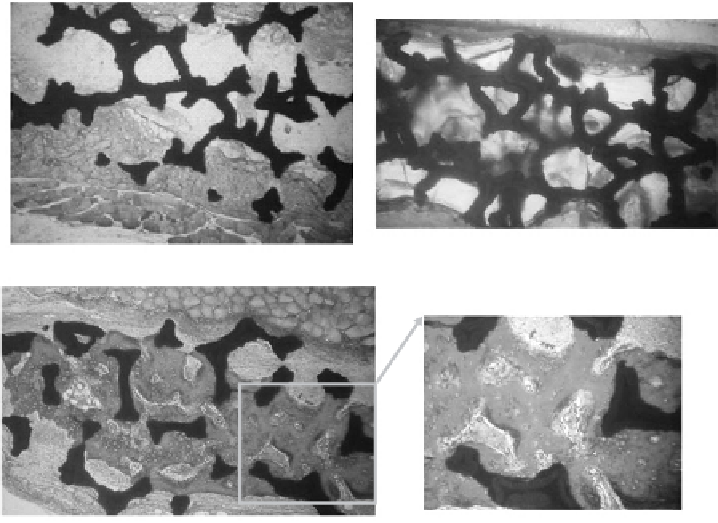

Uncoated tantalum

Conventional HA coated tantalum

Nanocrystalline HA coated tantalum Nanocrystalline HA coated tantalum

Figure 7.4.

Histology of rat calvaria after 6 weeks of implantation of uncoated tantalum,

conventional HA coated tantalum and nanocrystalline HA coated tantalum. Greater amounts

of new bone formation occurred in the rat calvaria with implanting nanocrystalline HA coated

tantalum compared to uncoated and conventional HA coated tantalum. Red represents new

mineralized bone and blue represents unmineralized tissue. Adapted and redrawn from [131].

(See color insert.)

or cavities since it showed good tissue incorporation, high biocompatibility and

rapid osseointegration [56].

To demonstrate the versatility of nano ceramics, similar tendencies also

appeared for nanophase alumina, zirconia and titania. A 51% increase in osteo-

blast adhesion and a 235% decrease in fi broblast adhesion in a four-hour period

were observed on alumina as grain size decreased from 167 to 24 nm [16]. More-

over, osteoblast adhesion increased by 146% and 200% on nanophase zirconia

(23 nm) and titania (32 nm) compared to microphase zirconia (4.9

μ

m) and titania

(4.1

m), respectively, when normalized to projected surface area [57]. Further-

more, increased collagen synthesis, alkaline phosphatase activity and calcium

mineral deposition by osteoblasts were observed on nanophase zirconia, titania

and alumina (theta + delta crystalline phase) compared to conventional equiva-

lents [48,57] .

To determine the role of nano ceramics in fi ghting implant infection, vari-

ous bacteria functions were recently investigated on nanophase ceramics. For

instance,

Staphylococcus epidermidis

(a common bacterium in human skin)

μ

Search WWH ::

Custom Search