Biomedical Engineering Reference

In-Depth Information

8

8

6

6

4

4

μ

m

μ

m

2

8

2

8

6

6

4

4

0

2

0

2

0

m

(a) 2.12

μ

m grain size titania

μ

μ

m

0

(b) 32

nm grain size titania

0.8

0.8

0.6

0.6

μ

m

0.4

0.4

μ

m

0.2

0.2

0.8

0.8

0.6

0.4

0

0.6

0

0.4

0.2

0.2

0

μ

m

μ

m

0

(c) 177

nm grain size alumina

(d) 23

nm grain size alumina

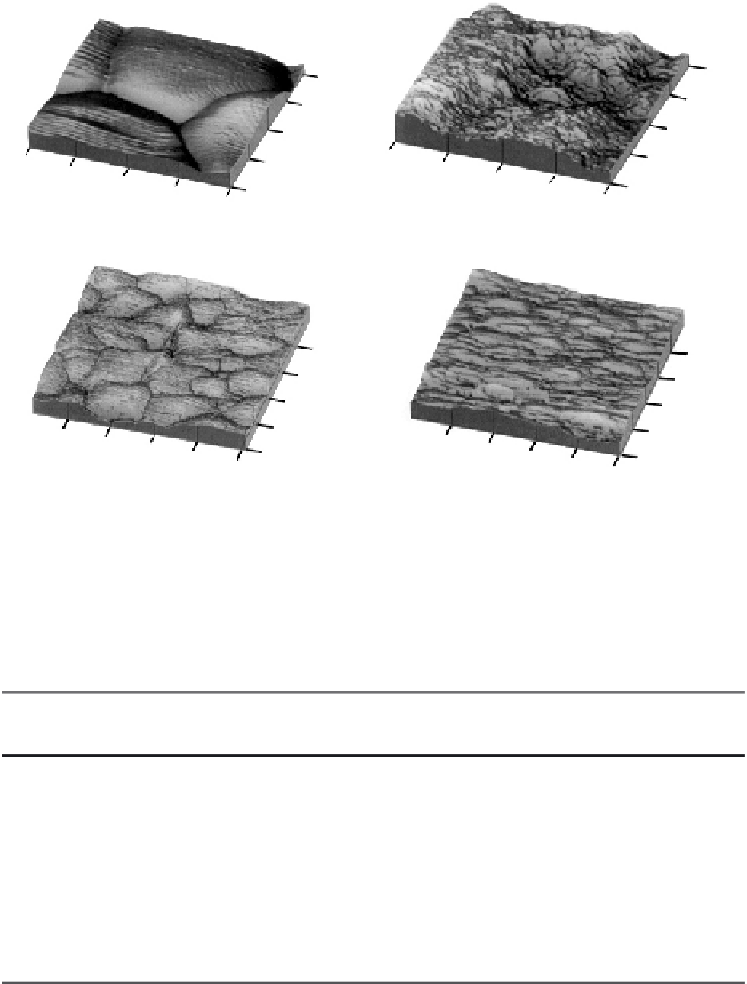

Figure 7.3.

Atomic force microscopy images of titania and alumina. (a) and (c) represent

conventional titania and alumina, respectively, and (b) and (d) represent nanophase titania

and alumina, respectively. Adapted from [14].

TABLE 7.1. Nanophase and Conventional Ceramic Structure and Surface Wettability, Data

is From [16]

Pore diameter

(nm)

Surface

roughness (nm)

Contact angle

(degrees)

Material

Porosity (%)

24 nm alumina

4.5

0.69

20

6.4

±

0.7

45 nm alumina

3.4

1.11

19

10.8

±

1.3

167 nm alumina

2.4

2.94

17

18.6

±

0.9

39 nm titania

4.1

0.98

32

2.2

±

0.1

97 nm titania

3.8

1.91

24

18.1

±

3.2

4520 nm titania

3.2

23.3

16

26.8

±

2.8

67 nm HA

1.1

0.66

17

6.1

±

0.5

132 nm HA

1.1

1.98

11

9.2

±

0.4

179 nm HA

1.1

3.10

10

11.5

±

1.1

In order to illustrate the advantages of nanophase ceramics in terms of

surface properties for orthopedic applications, calcium phosphate derivatives are

perfect examples—such as HA, tricalcium phosphate, calcium carbonate and

bioglass which have extensive applications in orthopedic implants [49]. Since

they share a similar crystal structure and chemical composition to natural bone,

Search WWH ::

Custom Search