Biomedical Engineering Reference

In-Depth Information

mental physical properties are interconnecting macroporosity and appropriate

microporosity [19,20].

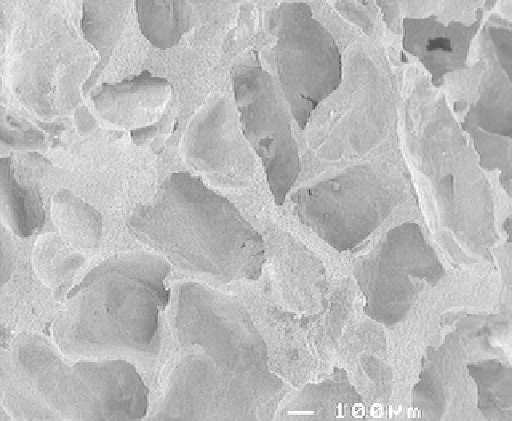

Macroporosity in BCP ceramic is introduced by incorporating volatile mate-

rials (e.g., naphthalene, hydrogen peroxide or other porogens), heating at tem-

peratures of less than 200 °C and subsequent sintering at higher temperatures

[19,21-25]. Macroporosity is formed as a result of the release of the volatile ma-

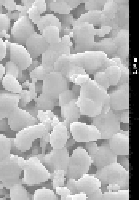

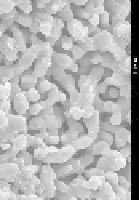

terials (Figure 4.1). Microporosity is a consequence of the temperature and dura-

tion of sintering [20]: the higher the temperature, the lower the microporosity

content and the lower the specifi c surface area (Figure 4.2).

At present, commercial BCP products of different or similar HA/

- TCP

ratios are manufactured in many parts of the world and their successful use in

medicine and dentistry has been reported [11,26-31]. The total porosity (macro-

porosity plus microporosity) of these products is reported to be about 70% of the

bioceramic volume. Current BCP commercial products with HA/

β

β

- TCP ratios

Figure 4.1.

Macroporosity of MBCP observed with SEM.

Figure 4.2.

SEM of discs sintered at 1050 °C (D1, D2, and D3) and at 1200 °C (D4, D5).

Search WWH ::

Custom Search