Biomedical Engineering Reference

In-Depth Information

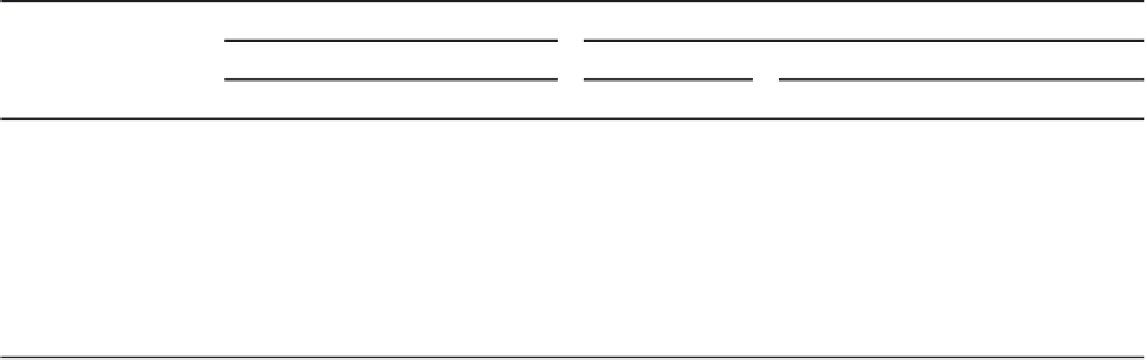

TABLE 3.5. Friction and Wear Properties of Investigated Biocomposites Compression Moulded Under Optimized Processing Conditions

(130 °C, 0.5 h, 5 ton load). The Details of the Tribological Properties Can be Found Elsewhere

10

− 6

m m

3

/Nm)

Sample Designation

Steady state COF

Wear rate (

×

Counterbodies

Zirconia

Steel

Alumina

Zirconia

Steel

Alumina

Environment

Air

SBF

Air

SBF

Air

SBF

Air

SBF

Air

SBF

Air

SBF

HDPE

0.05

0.04

0.09

0.07

0.07

0.05

13.8 ± 0.5

8.1 ± 0.2

25.2 ± 0.5

11.5 ± 0.2

8.9 ± 0.3

8.3 ± 0.3

HDPE - HAp (20 vol%)

0.08

0.07

0.09

0.08

0.08

0.05

7.1

±

0.4

4.9

±

0.4

9.5

±

0.4

7.8

±

0.4

4.9

±

0.2

4.6

±

0.2

HDPE - Al

2

O

3

(20 vol%)

0.12

0.06

0.13

0.09

0.13

0.07

4.3 ± 0.6

2.3 ± 0.3

8.7 ± 0.6

4.6 ± 0.3

4.2 ± 0.2

3.3 ± 0.2

HDPE - HAp (20 vol%) -

Al

2

O

3

(20 vol%)

0.11

0.05

0.13

0.09

0.12

0.11

1.8

±

0.4

1.1

±

0.7

3.9

±

0.4

2.3

±

0.7

0.7

±

0.1

0.6

±

0.1

HDPE - Al

2

O

3

(40 vol%)

0.15

0.07

0.15

0.11

0.16

0.12

0.9

±

0.5

0.2

±

0.4

2.8

±

0.5

1.8

±

0.4

0.3

±

0.1

0.1

±

0.1

HDPE - HAp (40 vol%)

0.09

0.07

0.11

0.09

0.09

0.11

3.9 ± 0.3

3.4 ± 0.6

6.6 ± 0.3

4.9 ± 0.6

2.5 ± 0.2

3.0 ± 0.2

[94] .

Search WWH ::

Custom Search