Biomedical Engineering Reference

In-Depth Information

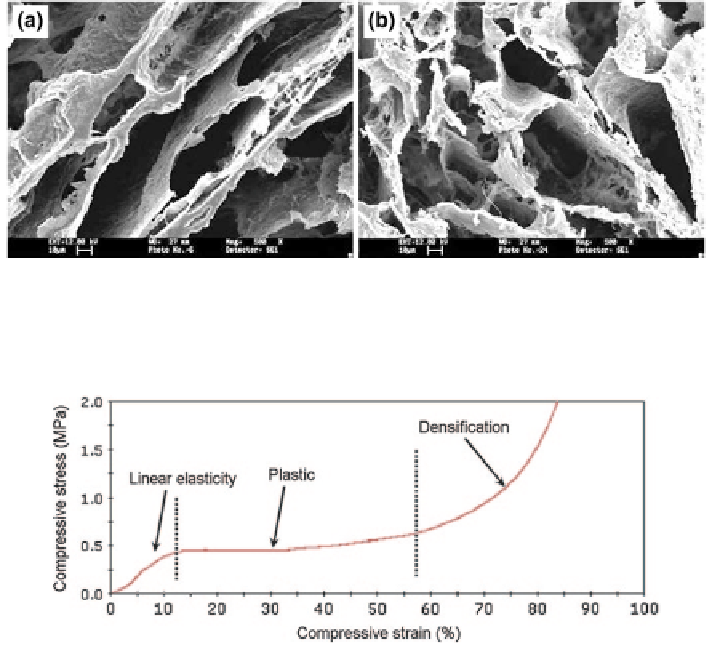

Fig. 3.4

SEM micrographs of PHB scaffolds fabricated from:

a

5 % PHB emulsion and

b

7.5 %

(w/v) PHB emulsion

Fig. 3.5

Typical compressive curve of the 10 % (w/v) PHBV scaffolds. Region I: Linear elastic-

ity; Region II: Plateau; Region III: Densification

used to align the structural elements both in the form of three-dimensional porous

structures and two-dimensional oriented surface patterns (Zhang et al.

2005

;

Sultana and Wang

2008a

,

b

).

Figure

3.4

shows the SEM micrographs of the PHB scaffold produced from

a PHB/chloroform/acetic acid mixture with a polymer concentration of 5 and

7.5 % (w/v). The microstructure of the PHB scaffold was similar to that of

PHBV scaffold fabricated from the same concentration and same processing

parameters.

Typical compressive stress-strain curve for one single scaffold (10 % w/v) is

given in Fig.

3.5

. The compressive properties of the PHBV scaffolds increased

with the increasing emulsion concentration. The scaffolds of 7.5 % (w/v) poly-

mer solution had the compressive modulus of 1.4

±

0.61 MPa in the 2.5-7.5 %

strain range whereas the scaffolds of 12.5 % (w/v) had the compressive modulus

of 6.41

±

1.03 MPa in the same strain range. The typical compressive stress-strain

curves have the three regions as shown in Fig.

3.5

. From Fig.

3.5

, it was observed

Search WWH ::

Custom Search