Biomedical Engineering Reference

In-Depth Information

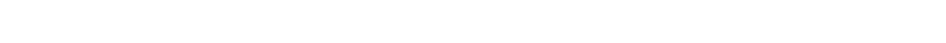

Initiate

quality risk management process

PHA

1. Define boundaries

Risk assessment

2. Hazard identification

Hazard identification

U

n

a

c

c

e

p

t

a

b

l

e

3. Identify causes and major effects

Risk analysis

4. Determine severity of effects

5. Estimate likelihood of occurrence

Risk evaluation

Risk control

6. Suggest corrective/preventive measures

Risk reduction

Risk acceptance

7. Qualitative ranking

8. Recommend mitigations

Output/report and implementation

Risk review

9. Implement and update

Review event

Figure 2.2

How preliminary hazard analysis fits in the risk management process.

2.4.2 Failure Mode Effects Analysis (FMEA) and Failure Mode Effects and

Criticality Analysis (FMECA)

2.4.2.1 Description

A failure mode effects analysis (FMEA) is a systematic

inductive risk analysis of a system to identify the potential failure modes, their

causes and effects. An FMEA may also be the procedure by which each potential

failure mode in a system is analyzed to determine the results or effects thereof

on the system and to classify each potential failure mode according to its sever-

ity. An FMEA requires product and process knowledge. It can be applied to a

manufacturing operation to analyze the effect on product or process [4].

In addition to FMEA, there is also failure modes, effects, and criticality anal-

ysis (FMECA). FMECA is an extension to the FMEA to include a means of

ranking the “criticality” of the failure modes to allow prioritization of controls or

mitigations. It is not uncommon that the terms FMEA and FMECA are used inter-

changeably. However, by definition, FMEA stops with scoring severity and prob-

ability of occurrence. If it involves matrices (for ranking and prioritization), risk

priority number (RPN), or ranking, the failure analysis is technically FMECA.

The primary elements of an FMEA or FMECA include the following:

1. Define the question/system boundaries.

2. Identify potential failure modes.

3. Identify failure effects (and causes).

4. Determine severity of effects.

5. Estimate likelihood of failure mode occurrence.

Search WWH ::

Custom Search