Biomedical Engineering Reference

In-Depth Information

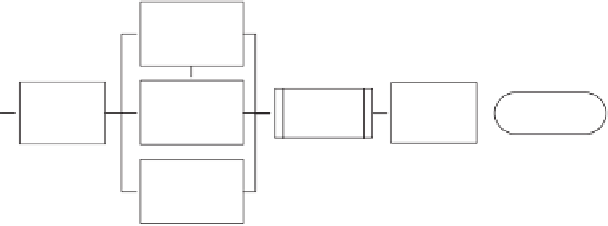

Assess severity of

excursions beyond

specification limits

Assess likelihood

of occurrence of

excursions beyond

specification limits

Assign

criticality to

individual

quality attribute

List individual

process

parameters

Create process

map

Assess risk

acceptability

Establish control

strategy

Assess

detectability of

excursions beyond

specification limits

Figure 12.2

Identification of critical process parameters.

evaluation can be based on retrospective information such as general scientific

knowledge, experimental data, and nonconformance results. Prospective eval-

uations can also be performed using the results of designed experiments, and

validation studies. Using this information, the evaluators may identify a subset

of parameters that have the potential to impact product safety and efficacy.

The next step in the process is to assign criticality to the parameters identified.

Criticality is assigned on the basis of three risk factors: severity, occurrence, and

detectability [5].

Severity is evaluated by assessing the impact of a process parameter on product

quality and patient safety. Determine how the parameter would impact a CQA

if it were to exceed its maximum operating range, for example, batch record

limits. In some instances, the maximum operating range for a parameter is well

within the range proved to be acceptable to product quality. In these instances,

an out-of-tolerance parameter would be expected to have minimal impact on

its associated CQA. In other instances, a parameter's maximum operating range

may be very close to its proven acceptable range and excursions have a greater

potential to impact product quality. Thus, its potential impact on product quality

may be very severe.

The next step in assigning criticality to a parameter is to assess the likelihood

that a parameter will exceed its maximum operating range. The likelihood of

exceeding an operating range can be identified through both experimental studies

and practical experience with the same or similar processes. Appropriate engi-

neering controls should be established to insure that processes operate within

specified ranges, thereby reducing the likelihood of an excursion.

Detectability is a factor that describes one's ability to identify an excursion

before it affects patient safety or product quality. Detectability evaluations should

consider both the ability to detect a process excursion and the ability to detect

the failure of a quality attribute. Detectability is a mitigating factor in that it

facilitates the identification of potential problems and permits corrective actions to

be performed to preclude the product and/or release of a nonconforming product.

Taken together, the three factors, severity, likelihood, and detectability define

the criticality of a process parameter. In an FMEA analysis, the product of the

Search WWH ::

Custom Search