Biomedical Engineering Reference

In-Depth Information

Manufacture of a solid product

Raw materials

Storage

Finish processing

Formulation

Dispensing

Materials

management

API/excipient/

water quality

Supplier

management

Materials

management

Compression

Granulation

Drying

Film coating

Branding

Milling

Packaging

Blending

Solid product

Environmental control

Training

Validation

Maintenance/

calibration

Cleaning/storage

Interventions

Cleaning

Materials flow

Protective gear

Fit for use

Hygiene

Facility

People

Equipment

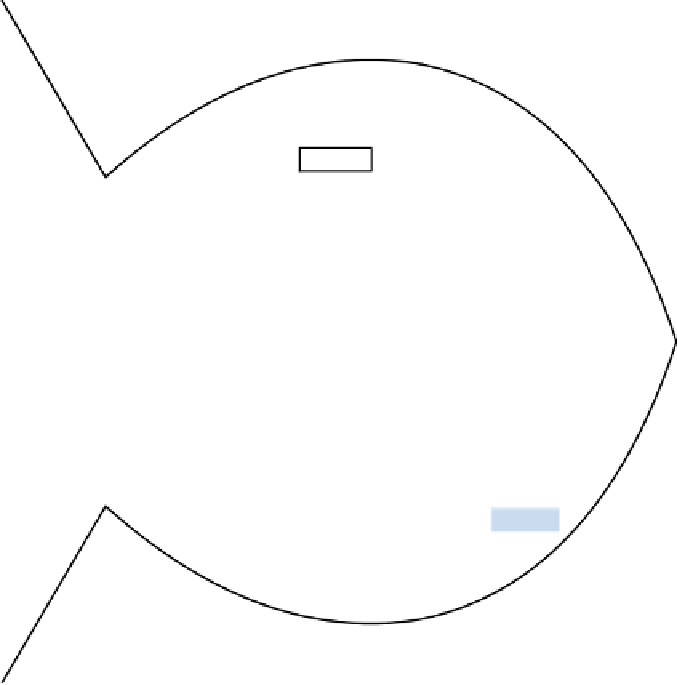

Figure 11.1

Example of a cause and effect diagram showing the manufacture of a solid

product. (

See insert for color representation of the figure

.)

At first it may be best to start out by identifying all the manufacturing steps

and inputs for a particular product. There are tools that can help. For example,

one tool is a cause and effects diagram also known as a fishbone diagram [17].

Figure 11.1 is an example of a fishbone diagram where all the processes involved

in the manufacture of a solid tablet are listed.

In this fishbone diagram, the top half of the fishbone contains the different

major steps of the manufacturing process starting with the receipt of incoming

raw materials in the warehouse (at the head of the fishbone) through the formu-

lation steps (e.g., dispense, blend), the finish process steps (e.g., compression,

packaging), and ending with the finished product storage in the warehouse (near

the tail of the fishbone). The bottom half contains components that support the

manufacturing process and would have an impact on the outgoing product quality:

facility, equipment, and people.

Search WWH ::

Custom Search