Biomedical Engineering Reference

In-Depth Information

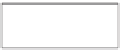

Engineering/construction/installation

Commissioning

User

requirement &

basis of design

development

Qualification

Design review

Design

qualification

Equipment

fabrication

Factory

acceptance

testing

Equipment

installation

Installation

verification/

qualification

Site

acceptance

testing

System

start-up

Engineering

studies

Operational

verification/

qualification

Process

performance

qualification

Figure 7.2

Relationship between engineering, commissioning, and qualification.

the systems and equipment are fabricated and installed. Commissioning repre-

sents the phase which establishes that the systems and equipment are designed

and functioning as intended. Qualification represents the phase which confirms

or proves that the systems are suitable for and capable of functioning correctly.

There is overlap between phases and activities within each phase. This overlap

provides the opportunity to share and leverage information. The degree of over-

lap and which activities fall into each phase will in large part depend on the

company's experience and confidence in the people performing these activities

and the systems in place for controlling these activities.

Healthcare product companies have an obligation to manufacture and distribute

products that are safe and effective. There is a regulatory requirement that these

companies assure that procedures and processes are in place to do so consis-

tently [6]. To meet this requirement, manufacturing processes affecting product

quality must be designed to control variables to the extent that the outcome is

predictable and consistent. The processes must be validated to prove that these

control measures are effective. A validated process relies on mechanical systems

Search WWH ::

Custom Search