Biomedical Engineering Reference

In-Depth Information

2

Friability

1.8

1.6

1.4

1.2

Design

space

1

0.8

0.6

Dissolution

0.4

0.2

0

40

42

44

46

48

50

52

54

56

58

60

Parameter 1

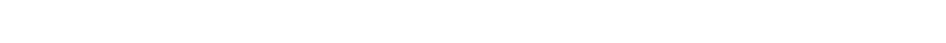

Figure 5.7

To show an example of design space (proposed design space, comprising

the overlap region of ranges for friability and or dissolution) Ref ICH Q8R2 [1].

variety of controls, such as automated process controls, manual controls, standard

operating procedures (SOPs), etc., to assure product quality. Some product

controls may be highly product specific. For example, it may be necessary to

control particle size distribution of an aerosol product to assure patient efficacy

and this, in turn, may highlight the need to control CPPs at micronizing and

blending unit operations. The control strategy should provide a clear rationale

as to how the product CQAs are assured at all stages of manufacture.

Hand in hand with the product control strategy is the need to consider the

requirements of ICH Q10, [3] the PQS. The PQS is defined in ICH Q10 [3]

as, “

a management system to direct and control a pharmaceutical company with

regard to quality

.” The product-specific controls and broader GMP controls that

apply to more than one product (such as the adequacy of changing facilities

for operators to dress into pharmaceutical clothing) should be integrated with

the PQS and at the same time permit business requirements, such as operational

efficiency, general safety, health and environmental considerations, financial, etc.,

to be met.

Finally, in regard to the QbD flow diagram in Figure 5.1, there is

Continual

Improvement

. This is to ensure that as knowledge is gained over the life cycle of

the product, such knowledge can be used to seek improvements to both products

and processes. For example, it may be that practical manufacturing experience

Search WWH ::

Custom Search