Biomedical Engineering Reference

In-Depth Information

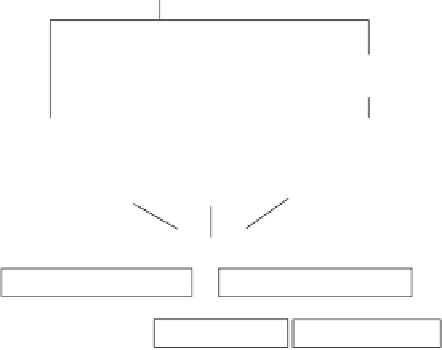

PEO

Macromonomer

(vinyl-PEO)

PEO-F

(activated PEO)

Homopolymer

or IPN

formation

Physical adsorption/

chemical

immobilisation

Grafting

copolymerisation

Block

copolymerisation

Physical

adsorption

Immobilisation

PEO-modified materials

PEO-containing material

Coating material

Blending additives

2.1

Molecular design of PEO-modifi ed surface (IPN

=

interpenetrating

network).

exhibited excellent blood compatibility. PEO can also be grafted chemically

onto numerous polymeric surfaces, such as polyethylene (PE), PU (Han

et al.

, 1993), haemodialysis cellulose membranes (Akizawa

et al.

, 1989) and

polytetrafl uoroethylene (PTFE) (Allmer

et al.

, 1990). PEO-modifi ed hae-

modialysis membrane surfaces have been found to reduce complement

activation (Akizawa

et al.

, 1989).

PEO-containing polymers can be built by block copolymerisation. Lee

et

al.

(1989, 1990) synthesised copolymers of alkyl methacrylates with methoxy

PEO methacrylates. The material produced can be used for coating. The

PEO surface prepared by adsorption of this synthesised PEO-grafted copo-

lymer showed effi cient protein-resistant character. Bergström

et al.

(1992)

utilised PEO to coat polystyrene a surface to achieve a reduced fi brinogen

adsorption. For a strong retention of PEO at the modifi ed surface, Lens

et al.

(1997) developed alkyl-PEO surfactants, which contained a terminal

hydroxyl, sulphate or carboxylate group. By surface coating with these

surfactants, followed by argon plasma treatment, a PEO strongly bound

surface could be achieved.

PEO has been widely applied as a soft segment for PU biomaterials and

PEO-PU segmented hydrogels have demonstrated improved blood com-

patibility in terms of protein adsorption and complement activation (Yu

et al.

, 1991).

PEO can be immobilised on surfaces by the Williamson reaction and

this has been employed for PEO modifi cation of PVC (Lakshmi &

Jayakrishnan, 1998).

Search WWH ::

Custom Search