Biomedical Engineering Reference

In-Depth Information

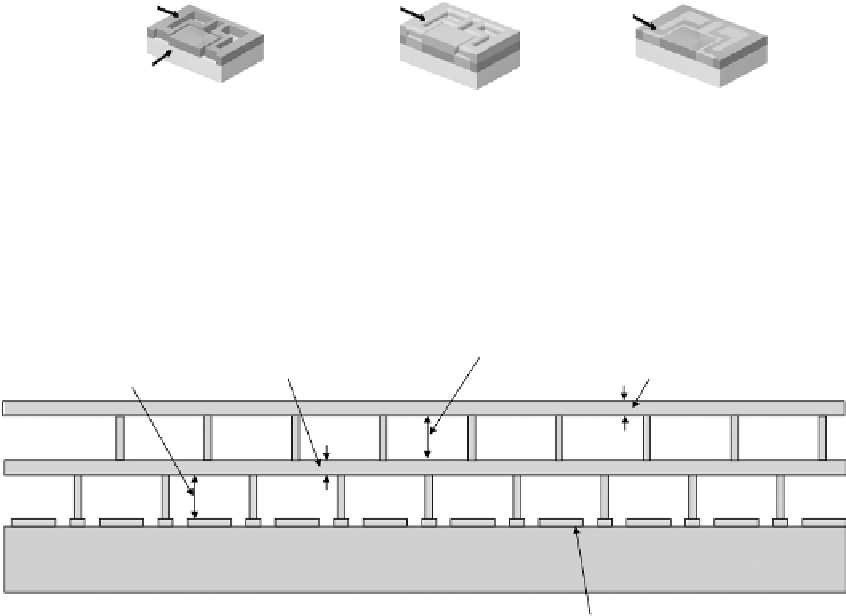

Sacrificial

metal

Structural

metal

Completed

first

layer

Substrate

(a) Patterned deposition

(b) Blanket deposition

(c) Planarization

FIGuRE 8.37

Overview.of.the.EFAB.process..(a).A.LIGA.process.is.used.to.electrodeposit.a.patterned.sacriicial.

metal,.such.as.copper,.on.top.of.a.substrate..(b).A.blanket.electrodeposition.of.a.structural.metal,.such.as.nickel,.

occurs.on.top.of.the.sacriicial.metal..(c).Using.polishing.techniques,.the.structural.metal.is.then.polished.back.to.

the.sacriicial.layer,.completing.the.irst.layer..he.process.can.be.repeated.in.cycles.to.build.up.multiple.sacriicial.

and.structural.layers.to.form.more-complex.structures..(Credit:.EFAB.process.)

5-8

μ

m spring

layer

30

μ

m gap

Splits (2): 20

μ

m,

30

μ

m gap

4

μ

m mirror layer

WMS-15 substrate (1.0mm)

Counter electrode

≈

1

μ

m

FIGuRE 8.38

Cross. section. of. a. high-stroke. deformable. mirror. for. fabrication. in. a. HARM. process.. he. mir-

ror.was.fabricated.in.two.splits..One.split.had.a.20-μm-thick.gap.between.the.counter.electrode.and.spring.layers..

he other.split.had.a.30-μm-thick.gap..he.structural.material.was.gold,.and.the.sacriicial.material.was.copper..he.

mirror.was.formed.on.top.of.a.1-mm-thick.glass-ceramic.substrate.(WMS-15).that.was.thermally.matched.to.the.

gold.structural.layers..Not.shown.in.this.igure.are.small.etch.release.holes.that.were.included.to.allow.the.etchant.

to.remove.the.sacriicial.layers.of.copper..(From.Fernandez,.B..R..and.J..Kubby,.

J Micro/Nanolitho MEMS MOEMS.

,.

9,.041106-1,.2010.)

A.cross.section.of.the.inal.structure.is.shown.in.Figure.8.38..he.mirror.is.formed.on.top.of.a.glass-

ceramic.substrate.(WMS-15,.Ohoro).that.has.a.coeicient.of.thermal.expansion.(CTE).closely.matched.

to.the.CTE.of.gold..he.gold.layers.include.a.counter.electrode.layer.for.the.electrostatic.actuators.that.

is.≈1.μm.thick..his.layer,.which.was.not.released,.was.deposited.onto.a.chrome.adhesion.layer.on.the.

WMS-15.substrate..he.next.structural.layer.was.a.spring.layer,.5-8.μm.thick.that.provided.a.mechani-

cal. restoring. force. for. the. electrostatic. actuator. formed. between. this. layer. and. the. counter. electrode.

layer..A.copper.sacriicial.layer.provided.a.gap.20-30.μm.thick.between.the.counter.electrode.and.the.

spring.layers..From.the.aforementioned.discussion.of.electrostatic.actuators,.this.should.allow.one-third.

of.the.initial.gap.or.7-10.μm.of.stroke.to.be.used.before.reaching.the.pull-in.instability..Slightly.more.

than.one-third.of.the.initial.gap.can.be.used.since.the.spring.layer.stretches.and.provides.a.nonlinear.

restoring.force..A.4-μm-thick.mirror.layer.is.deposited.on.top.of.a.post.layer.and.is.separated.from.the.

spring.layer.by.a.30.μm.gap.

A.number.of.diferent.electrostatic.actuator.structures.were.fabricated.using.their.process.to.avoid.

tilting.of.the.actuator.as.it.was.displaced..Solid.models.of.these.diferent.actuator.structures.are.shown.