Biomedical Engineering Reference

In-Depth Information

grown wafer is then processed accordingly to produce individual devices.

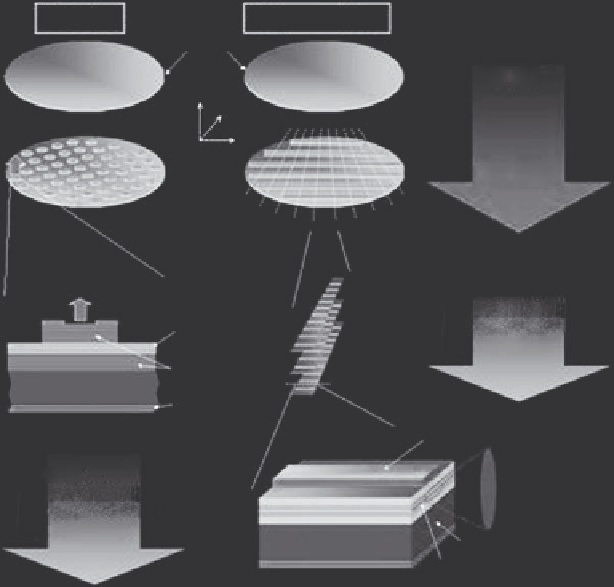

Figure 2.41 summarizes the differences between VCSEL and edge-emitter

processing.

In a VCSEL, the active layer is sandwiched between two highly reflec-

tive mirrors (dubbed DBRs) made up of several quarter-wavelength-thick

layers of semiconductors of alternating high and low refractive index. The

reflectivity of these mirrors is typically in the range of 99.5%-99.9%. As a

result, the light oscillates

perpendicular

to the layers and escapes through the

top (or bottom) of the device. Current and/or optical confinement is typi-

cally achieved through either selective-oxidation of an aluminum-rich layer,

ion-implantation, or even both for certain applications. The VCSELs can be

designed for “top-emission” (at the epi-air interface) or “bottom-emission”

(through the transparent substrate), in cases where “junction-down” solder-

ing is required for more efficient heat sinking, for example. Figure 2.42 illus-

trates different common types of VCSEL structures.

Edge-emitters

VCSELs

Wafer

Growth

Y

X

Z

Processing

Light output (circular beam)

Active

region

DBR

Edge-emitters:

- Dicing/cleaving

- Additional processing

Substrate

Contact

Contact

Light output

(elliptical beam)

VCSELs:

- Dicing into single

devices, or 1-D or 2-D

arrays

Substrate

Special coating

Active layer

FIGURE 2.41

Comparison of the growth/processing flow of VCSEL and edge-emitter semiconductor lasers.

(Courtesy of Princeton Optronics [PO] and Dr. Chuni Ghosh. With permission.)

Search WWH ::

Custom Search