Biomedical Engineering Reference

In-Depth Information

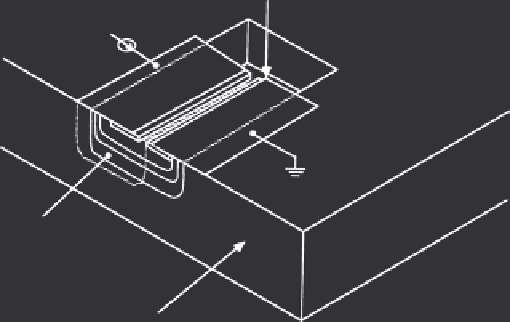

ON-chip

mirror

I

Semi-insulating

GaAs substrate

P

N

Zn

ALGaAs/GaAs DH structure

grown in an etched well

FIGURE 2.28

Schematic representation of the integratable TJS laser grown in an etched well. The on-chip

mirror facet is formed by the undercut mirror process.

lasers having two cleaved mirrors. The optoelectronic chip having a size of

1.8 mm × 1.8 mm operated at speeds up to 150 MHz [71].

More recently, a 1 Gb/s optoelectronic receiver chip was demonstrated [72].

The receiver chip was designed to digitally multiplex four high-speed input

signals. Two of the inputs are electrical and two are optical. The receiver

consisted of two back-to-back Schottky diode detectors, two amplifiers, a 4:1

MUX, and a laser driver. All of the components were fabricated on a semi-

insulating GaAs substrate using direct implantation MESFET technology.

The photodetector was fabricated on a semi-insulating substrate, thus

eliminating the need for epitaxial growth. The pulse response of the back-to-

back Schottky photodiodes [73] had rise and fall times for a range of bias volt-

ages between −10 and −15 V of under 100 ps, which is sufficient for a 1 Gb/s

operation of the receiver. The responsivity of the detector was measured to

be 2.0 A/W for a wavelength of 0.84 μm. The output of the detector is fed

into a three-stage amplifier, a preamplifier, a gain stage, and a buffer stage.

The preamplifier translates the current into a voltage and amplifies to the

proper GaAs logic levels by the gain stage, and the buffer stage is used as a

line driver for the input of the 4:1 MUX. The preamplifier had a gain of 20 dB

with a feedback around the second stage to improve its frequency response.

A similar effort on monolithic integration using a multiple quantum well

(MQW) laser with a ridge channel waveguide structure [74] is shown in

Figure 2.29. The MQW laser structure was grown by MOCVD and consisted

of five 100 GaAs wells separated by four 40 Å Al

0.2

Ga

0.8

As barriers. The ridge

waveguide was ion milled having a width of 5 μm. These integrated devices

Search WWH ::

Custom Search