Biomedical Engineering Reference

In-Depth Information

characteristics when making electro-optic modulators or lasers, because

the electric field is a maximum in the optical waveguiding layer. Optimum

coupling of the electrical and optical fields is obtained through the electro-

optic coefficient. Fourth, the heterostructure design naturally leads to the

integration of lasers, waveguides, and modulators without undue etching

of material.

5.7.2 Material Systems: Control of Loss, Refractive

Index, and Electro-Optic Effect

By choosing the AlGaAs system for waveguide fabrication, one is essen-

tially obtaining a wide range of freedom in the choice of band gap for the

material. By varying the percentage of the Al the band gap of the mate-

rial may be changed significantly. The band gap is directly related to the

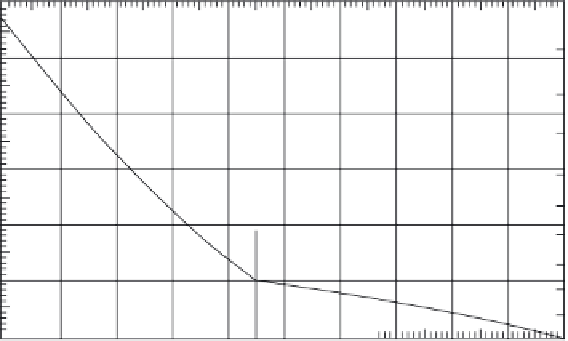

emission and absorption wavelengths of the material. Figure 5.16 shows

the band gap and related wavelength and photon energy of the AlGaAs

system for varying percentages of Al from 0% (GaAs) to 40%. Figure 5.17

shows the index of refractions of AlGaAs versus Al concentration for sev-

eral wavelengths. It is seen that by a proper choice of material composition

in the waveguide core and cladding regions a suitable guiding structure

may be designed.

The strip ridge should be aligned with either the (011) or the (110) crystal-

lographic direction for a modulating electric field perpendicular to the sub-

strate (100) direction. The change in refractive index due to the electro-optic

effect is

0.86

0.84

0.81

0.79

0.76

0.74

0.71

0.69

0.66

0.64

0.61

0.59

0.56

0.00

1.4

1.5

1.6

1.7

1.8

1.8

1.9

2.0

2.1

2.1

2.2

Direct (gamma valley)

Indi

rect (X valley)

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.80

0.90

1.00

Aluminum concentration

FIGURE 5.16

Minimum energy gap versus aluminum concentration.

Search WWH ::

Custom Search