Biomedical Engineering Reference

In-Depth Information

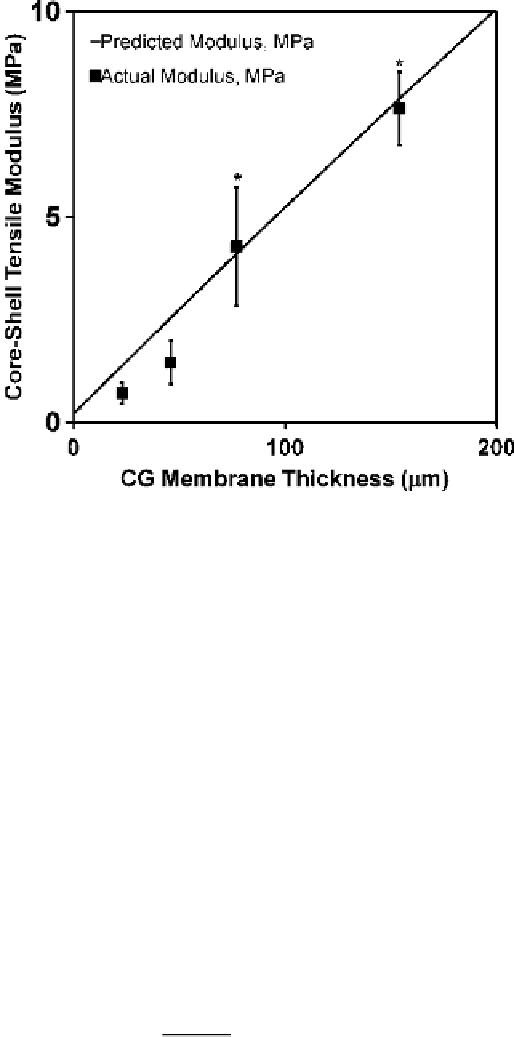

Fig. 16.8

Core-shell composite Young's modulus (

n ¼

6) compares favorably to layered

composites theoretical prediction. The close agreement is indicative of integration of the mem-

brane shell with scaffold core. Shell thicknesses: 23, 45, 78, and 155

m. Error bars: Mean

SD.

m

(Reproduced, with permission, from Caliari et al. [

1

])

After separate mechanical characterization of aligned CG scaffolds and CG

membranes, CG scaffold-membrane composites were fabricated and characterized

using membranes ranging in thicknesses from 23

m(1%

2

wrapped twice around scaffold). These scaffolds demonstrated dramatically

increased tensile moduli over CG scaffold controls (no membrane shell) with a 36-

fold increase observed for the 155

m(0.5%1

)to155

m

m

mmembrane thickness. Experimental results were

compared to predictions from layered composites theory. Layered composites theory

has previously been used to accurately predict the tensile properties of multicompo-

nent materials based on the relative size of the individual components and their

separate moduli [

1

]. CG core-shell composite Young's modulus

ðE

composite

Þ

can be

predicted by the rule of mixtures as a function of scaffold core Young's modulus

ðE

scaffold

Þ

, membrane shell Young's modulus

E

membrane

,compositeradius(

r

), and

membrane thickness (

t

)[

1

]:

m

!

þ E

membrane

1

ð

r

t

Þ

!

2

2

ðr tÞ

E

composite

¼ E

scaffold

(16.1)

r

2

r

2

Experimental results correlate well with theoretical predictions, especially for

composites with the two thicker membranes (78, 155

m

m) (Fig.

16.8

). The close

Search WWH ::

Custom Search