Biomedical Engineering Reference

In-Depth Information

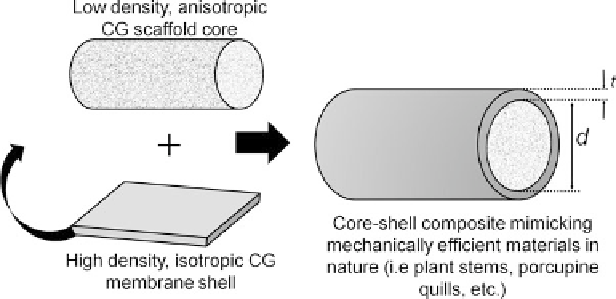

Fig. 16.5

Schematic of CG core-shell composite design

pulposus integrated with layered, aligned nanofiber mats mimicking the annulus

fibrosus region [

74

,

75

].

The CG scaffold-membrane composite paradigm was developed to avoid the

typical tradeoff for porous tissue engineering scaffolds between mechanical

properties (Young's modulus:

E

*) and bioactivity (permeability:

k

and porosity:

e

).

Briefly, previous experimental and cellular solids modeling studies have shown

that scaffold modulus increases with (

r

*/

r

s

)

2

(and is not affected by pore size)

but that scaffold permeability increases as (1

(

r

*/

r

s

))

3/2

[

57

,

58

]. Hence, to

increase CG scaffold elastic modulus by the two or three orders of magnitude

necessary for tendon applications (minimum 100 MPa hydrated modulus), the

corresponding increase in relative density would have adverse effects on overall

scaffold bioactivity (permeability and porosity). Taking inspiration from core-

shell structures in nature [

56

], the scaffold-membrane composite design can help

overcome these limitations.

16.4.1 Fabrication of Aligned CG Scaffold-Membrane

Composites via Liquid-Solid Phase Co-synthesis

The core-shell CG composite paradigm was implemented using the same

technologies developed to create multi-compartment CG scaffolds for

osteochondral tissue engineering. Here a high density (high tensile strength) CG

membrane was combined with a low density (porous) aligned CG scaffolds into a

single biomaterial via a liquid-solid phase co-synthesis method [

1

,

47

] (Fig.

16.5

).

As a precursor for using these composites for tendon repair, the scaffold core

contained a longitudinally aligned, anisotropic pore microstructure fabricated

using a recently developed directional freeze-drying approach [

53

]. The aligned

microstructure was hypothesized to improve construct regenerative capacity by

increasing the modulus in the direction of alignment and by providing contact

Search WWH ::

Custom Search