Biomedical Engineering Reference

In-Depth Information

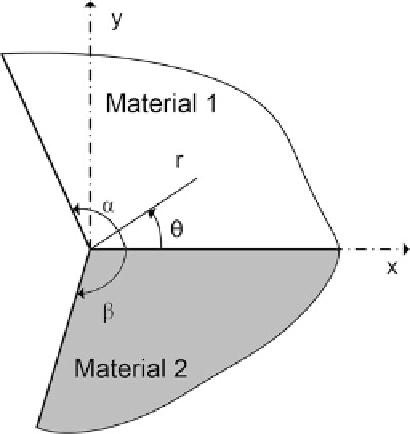

Fig. 1.9

Geometry in the

vicinity of the free edge at the

attachment between

two dissimilar materials

(the

z

-axis is perpendicular

to the plane)

effect of such a layer in dental and metal-to-bone interfaces and at the tendon-

to-bone insertion site has already been discussed. While the stiffness and stress

analyses could be conducted along the lines of previously cited studies, the

fracture problem is more challenging. One complication is related to several

possible scenarios of the crack propagation. For example, cracking can occur

along the bondline between the interfacial layer and one of the dissimilar

materials or alternatively, cracking can occur within the interfacial layer itself.

Finally, it is also possible for the crack to “depart” from the interfacial region

and propagate into one of the joined materials.

The orientation of the crack may be predicted adopting one of several available

criteria applicable to fracture in a functionally graded material. For example, such

criteria can include [

21

]:

- The maximum hoop stress criterion, i.e., the crack propagates along the axis of

the maximum hoop stress.

- The maximum strain energy release rate criterion, i.e., the crack propagates

along the axis corresponding to the maximum strain energy release rate.

- The maximum strain energy density criterion, i.e., crack propagation occurs with

the direction corresponding to the smallest strain energy density.

The previous discussion implies that an optimum interface is likely to be graded

in the direction perpendicular to the surfaces of joined dissimilar materials. The

case of a uniform interface can be treated as a particular case of the more general

graded counterpart. Numerous relevant problems have been considered in engi-

neering science (e.g., [

22

-

24

]), although the optimization of the interface arresting

the crack propagation has not been attempted.

Search WWH ::

Custom Search