Biomedical Engineering Reference

In-Depth Information

to the tangent of the surface. Motivated by this experiment, Gao et al. [

7

] performed

finite element calculations of the pull-off force of a single seta and, as shown in

their results plotted in Fig.

10.8b

, confirmed theoretically that the pull-off force of

gecko's seta strongly varies with the pulling orientation, with the maximum value

achieved around

' ¼

30

.

In the case of single contact by an elastic tape or seta, the anisotropic behavior of

the pull-off force can be attributed to the asymmetric alignment and slender

structure of the contacting object. While this behavior suggests that the pull-off

force of a single hair in contact can be controlled by pulling in different directions,

an open question is whether the adhesive strength of a large array of fibers or a

macroscopic attachment pad in contact with a rough surface would show similar

behaviors. To address this question, we shall consider the issue of releasable

adhesion from the point of view of continuum interfacial failure mechanics.

We use theoretical modeling and numerical simulations to show that strong elastic

anisotropy on the continuum level, achieved via fibrillar microstructures or some

other means, plays a key role in releasable adhesion: a strongly anisotropic elastic

solid also exhibits a strong orientational dependence of the pull-off force, similar to

the behavior of a single seta studied by Gao et al. [

7

].

10.4.3 Directional Adhesion Strength of an Anisotropic

Elastic Material

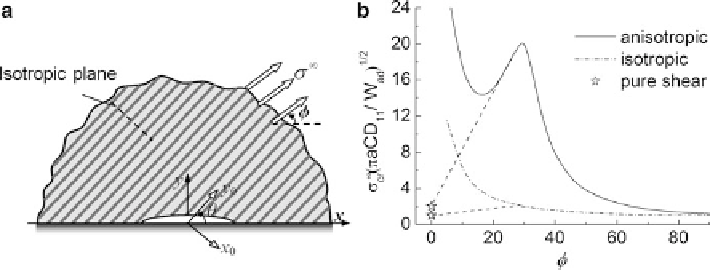

To illustrate the intrinsic orientation-dependence of adhesion strength of an aniso-

tropic elastic material in contact with a rough surface, we consider the linear elastic

plane-strain problem shown in Fig.

10.9a

where a transversely isotropic elastic half-

space (

y

0) is brought to contact with a rigid substrate. A plane-strain interfacial

Fig. 10.9

Releasable adhesion in three dimension. The pull-off stress of a strongly anisotropic

(transversely isotropic) elastic half-space sticking to a substrate. (

a

) An interfacial crack-like flaw

with width 2

a

is introduced as a representative contact flaw due to surface roughness or

contaminants. (

b

) Variation of the adhesion stress as a function of the pulling angle for the

anisotropic material in comparison with that for an isotropic material

Search WWH ::

Custom Search