Biomedical Engineering Reference

In-Depth Information

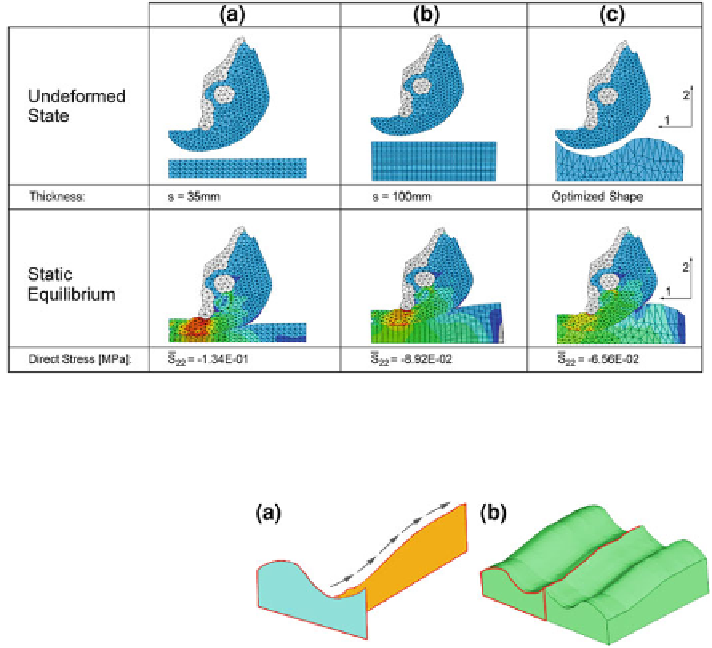

Fig. 7.47 Comparison of two different cushion shapes to the optimized transversal shape:

a block-shaped, 35 mm, b block-shaped, 100 mm, c optimized transversal shape

Fig. 7.48 a Extrusion of the

optimized transversal shape

along the contour of the

optimized sagittal shape, and

b resulting three-dimensional

geometry

Results indicate that direct stress at the skin surface is reduced by nearly 50 %

using the optimized cushion shape. Similar results can be observed at the fat-

muscle interface as well as deeper inside the muscle tissue.

Due to these simulation results, the approach of support shape optimization using

plane strain conditions as a basis to generate a continuum support geometry,

potentially reducing tissue stress seems practicable. Clearly, in the same manner, the

continuum model can be directly employed in the shape optimization process where

node coordinates of the 3D-cushion model are parameterized. Such an approach,

however, involves increased optimization time as well as potential convergence

difficulties due to increased model as well as contact interaction complexity.

7.2.4 Design Principles

In

Sect. 7.2.2

, Fig.

7.37

, different stages of tissue deformation are depicted during

the process of sitting down on a soft foam support. To quantify corresponding

tissue displacements, tissue thickness in the initial undeformed configuration,