Biomedical Engineering Reference

In-Depth Information

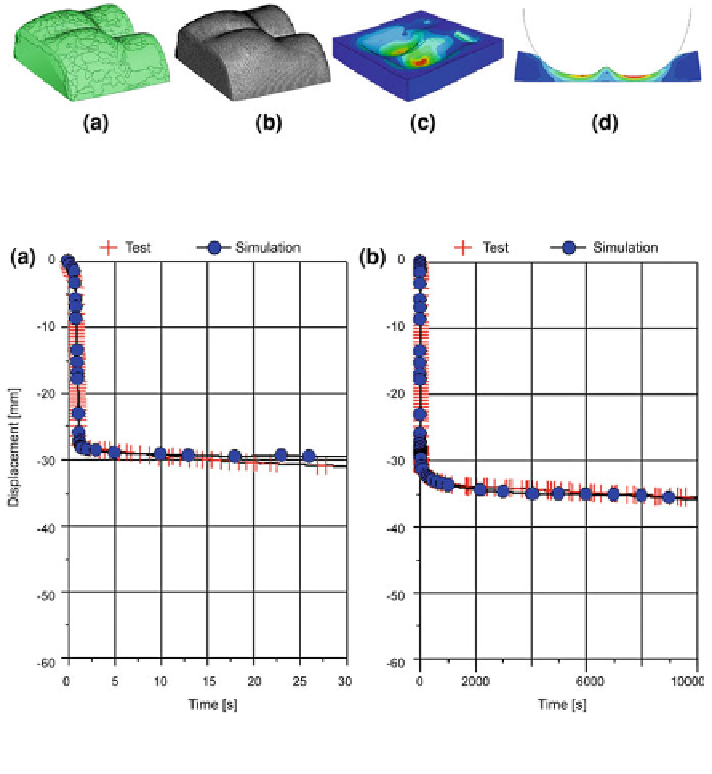

Fig. 4.18 Physical buttocks model: a CAD-surface data, b FE-Mesh, c deformed VE-foam

model and d rigid buttock model on VE-foam in section cut view

Fig. 4.19 Comparison of experimental HR-foam material data with simulation output: a zoomed

time range: 0-30 s and b time range: 0-10,000 s

node shell elements, and rigid body characteristics were assigned. All degrees of

freedom except the loading direction were constrained. In addition, point mass was

added to meet the experimental model weight.

Creep testing was performed as described in

Sect. 4.2.1.4

with HR-foam

material and VE-foam material, and buttock vertical displacement was measured

over 3 h. Comparison of experimental displacement-time recording and simula-

tion output are depicted in Fig.

4.19

for HR-foam material and Fig.

4.20

for VE-

foam material.

A Critical Review: The exclusive use of long-term material data in interaction

simulation, without considering time-dependence, underestimates the material

response in most cases. As the Figs.

4.12

and

4.13

show, exclusive use of the long-

term material response is not justified if the material very slowly, over hours or

even days, reaches steady state. Without information on material time-dependence,