Biomedical Engineering Reference

In-Depth Information

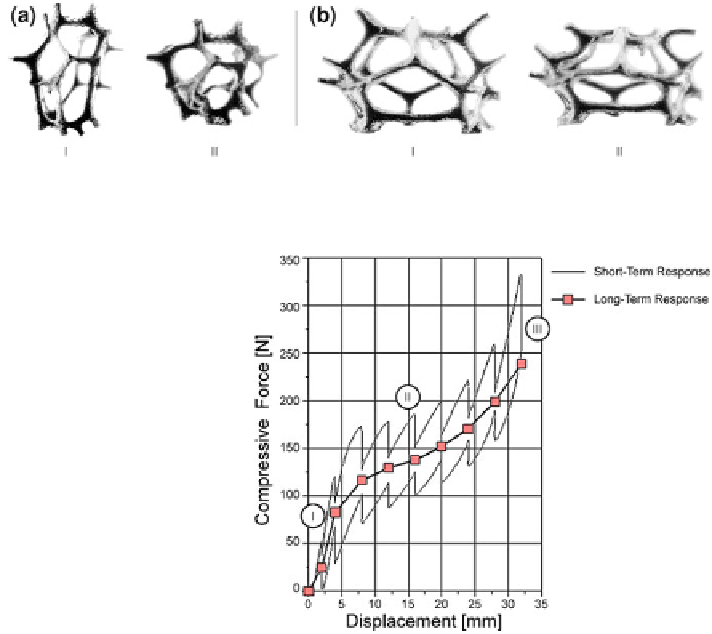

Fig. 4.3 PU-foam cells (a-I) undeformed configuration, (a-II) compressed along the rise direction

and (b-I) undeformed configuration, (b-II) compressed perpendicular to the rise direction

Fig. 4.4 Representative

force-displacement curve

obtained from stepwise

uniaxial loading of low-

density open-cell PU-foam.

Characteristic regions of

elastomeric foam behavior

are labeled: (I) linear elastic

at small strain, (II) elastic

buckling, and (III)

densification

The difference in material response is due to a possible elongation of foam cells

in the foaming (rise) direction. The cell structure and, as a result, the macro-

structure, is therefore geometrically (mechanically) anisotropic. Consequently, the

mechanical response of polymeric foams depends on the intrinsic properties of the

employed polymers, the cell architecture and the material of the cell walls. The

cell architecture is determined by the cell ligament dimensions and dimension

distribution of the cells making up the framework.

Mechanical Behaviour: In geometrically anisotropic cell structures, compression

loading perpendicular to the rise direction results in a nearly monotonic force increase,

whereas loading along the rise direction results in a distinct plateau in the load-

displacement curve. As noted in (Mills 2000), loading forces at 50% strain are about 3-

fold higher when loading perpendicular to the cell rise direction, compared to loading

along the rise direction. International standard regulations (ISO 3386, ASTM D-3574)

prescribe the compression force deflection value (CFD) for soft urethane foams to be

determined by compression perpendicular to the foam rise direction.

When loaded in compression, open-cell foam exhibits characteristic behaviour. A

representative material response from stepwise uniaxial compression loading of