Biomedical Engineering Reference

In-Depth Information

toring tool for enzyme catalyzed processes. The common criticism that bio-

sensors are not stable enough for on-line monitoring, is not convincing in the

field of biotransformations,because the enzymes for synthesis also have a lim-

ited process stability. On the contrary, the non-complex biotransformation

media should increase their process stability.

Recently,the ET was presented as an on-line monitor for biotransformation

processes (Lammers and Scheper,1996).Here,three different enzyme-catalyzed

processes of industrial interest were investigated.In the first example,the enzy-

matic production of

L

-ornithine was monitored via urea analysis. In this pro-

cess, arginase hydrolyzes

L

-arginine with the release of urea and

L

-ornithine.

Immobilized urease was set into the ET in order to monitor urea release, and

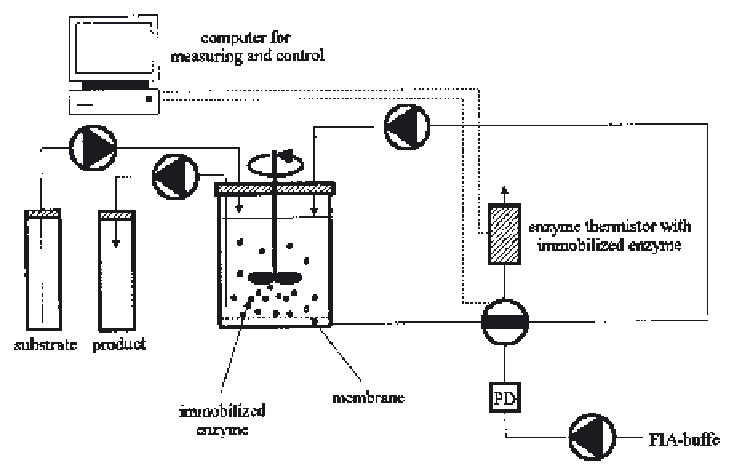

on-line data informed us of the progress of production.Moreover,a computer-

controlled set-up (Fig. 15) allowed us to remove the product at a nominal value

and to add fresh substrate (Fig. 16).

In further experiments,the ET was shown to monitor enzymatic

L

-methioni-

ne synthesis via amino acylase. Here, decreasing starting material data (

N

-

acetyl-

DL

-methionine) were of interest.The process was compared with native

and immobilized biocatalyst (Fig. 17).

In a third example,the production offructose was obtained.Here,the starting

material sucrose was hydrolyzed via invertase to fructose and glucose.The pro-

gress in hydolysis was monitored with an ET containing coimmobilized glucose

oxidase and catalase. Following the addition of glucose isomerase, it caused a

shift of ingredients to fructose (Fig. 18).In summary,the connection of enzyme

and (calorimetric) biosensor technology might be very effective for a number of

enzyme catalyzed processes.

Fig.15.

Computer controlled set-up for on-line monitoring of enzyme catalyzed processes

Search WWH ::

Custom Search