Biomedical Engineering Reference

In-Depth Information

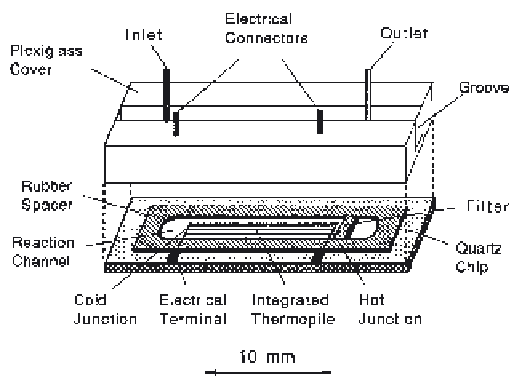

Fig. 5.

Schematic diagram of the thermal microbiosensor based on an integrated thermopile

fabricated on a quartz chip. Glucose oxidase immobilized on CPG beads was charged into the

channel

ion implantation and then annealed in nitrogen at 950 °C for 30 min. Next, the

layer was patterned by wet chemical etching, using negative photoresist as an

etch mask. Metalization was accomplished through aluminum vapour deposi-

tion and an additional photolithographic patterning procedure. As a final step,

the chip was annealed at 200 °C for 30 min. The surface of the chip was covered

by a 30

m thick layer of polyimide membrane to insulate the transducer

electrically from flow liquid. The voltage output per degree of the integrated

thermopile was about 2 mV/K at 22 °C.

On the chip,a silicone rubber membrane (0.32 mm thick was used to form the

microchannel (17.5

m

0.32 mm) and to serve as a seal between the chip and

the plexiglass cover. The inlet and outlet stainless steel tubing, as well as the elec-

trical connectors, were mounted on the cover. The entire unit was held together

with a screw-mounted delrin holder. This rather bulky construction was re-

quired in order to facilitate repeated access to the sensor chip. The CPG beads

were charged into the microchannel by sucking them in from the outlet end. The

beads were stopped at the hot junction using a filter made from a tiny piece of

kleenex tissue. Two thirds of the channel from the hot junction were filled with

the enzyme-containing beads. The remaining third was filled with similar beads

without any enzyme, in order to reduce carryover of heat to the cold junction.

¥

3.6

¥

2.3.2

Thermistor-Based Microbiosensor

The thermistor-based device (Fig. 6), is composed of a transducer chip

(21

0.57 mm), a spacer, and electrical and liquid flow connections. Five

thermistors (T

0

-T

4

) with a temperature coefficient of 1.7% per degree (25 °C)

¥

9

¥

Search WWH ::

Custom Search