Biomedical Engineering Reference

In-Depth Information

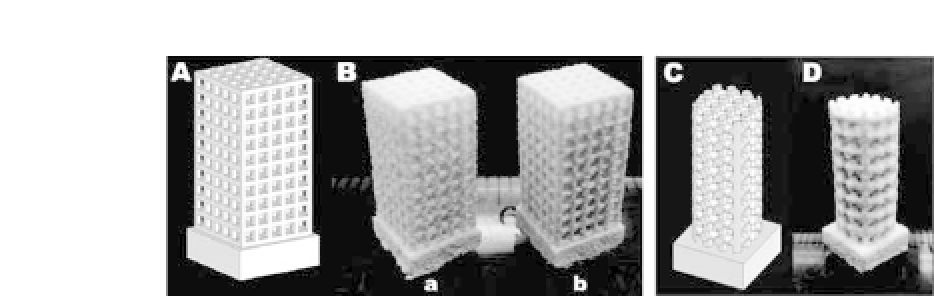

Figure 45.6.

Bar-shaped and rod-shaped scaffold models and sintered

scaffolds: (A) bar-shaped and (C) rod-shaped model in trimetric view;

(B)sinteredscaffolds,(a)PHBVscaffoldand(b)Ca-P/PHBVnanocomposite

scaffold, (D)sintered Ca-P/PHBV nanocomposite scaffold.

structure and handling stability, and hence loose microspheres

entrapped in the sintered scaffolds could be easily removed. The

macrostructure, including the height, width, and thickness, of sin-

teredscaffoldscouldbewellcontrolledbyselectingcarefullytheval-

ues of various SLS parameters. However, it was not easy to achieve

high accuracy for the pore size and strut size of scaffolds because

of the growth effect in the SLS process as well as the limitation of

resolution ofthe SLS machineused.

59

The typical layer morphology of bar-shaped PHBV scaffolds and

Ca-P/PHBV nanocomposite scaffolds is shown in Fig. 45.7. The SEM

imagesindicatedthatthemorphologyandarchitectureofeachlayer

of the scaffold were well preserved for both types of materials and

the pores were clearly identified and comparable to the designed

scaffold structure. The entrapped microspheres had been easily

removedfromthescaffoldsbymanualshaking.Withthecloseexam-

ination of the strut surface, as shown in Fig. 45.7b,d, it could be

seen that there was necking between adjacent microspheres and

nearly intact microspheres without obvious fusion also existed. The

presence of nearly intact microspheres could be explained as the

sticking of microspheres onto the sintered strut due to very small

melting of these microspheres caused by the heat generated during

the SLS process. The porosity of the designed scaffold model was

calculated to be 67.9% for the bar-shaped scaffold and 53.5% for

the rod-shaped scaffold using the SolidWorks

R

software. For sin-

tered scaffolds, the measured porosity values were 80.7

±

0.7% for

Search WWH ::

Custom Search