Biomedical Engineering Reference

In-Depth Information

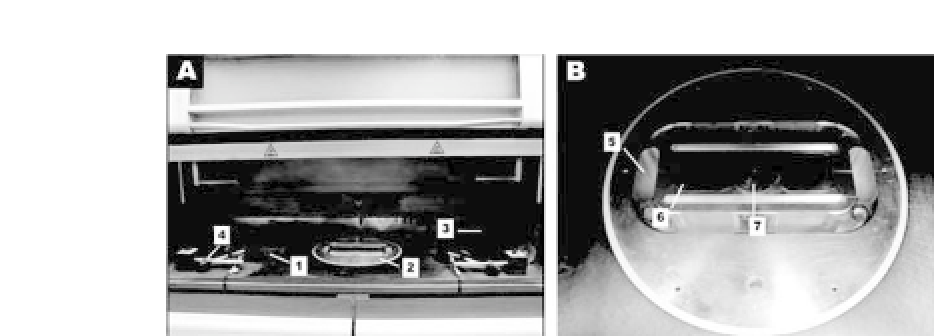

Figure 45.3.

(a) Sinterstation

R

2000 SLS machine; (b) miniature sinter-

ing platform for the modified Sinterstation

R

2000 SLS machine. (1: left

powder tank; 2: build part for original machine and miniature sintering

platform for the modified machine; 3: roller; 4: left sensor; 5: recycle bin;

6: left powder tank for the modified machine; 7: build part for the modified

machine.) See also ColorInsert.

required for a commercial SLS machine in building (sintering) solid

objects. A general view of the sintering section of a commercial

Sinterstation

R

2000 SLS machine (3D Systems, Valencia, CA, USA)

is shown in Fig. 45.3a. A modification of this SLS machine was con-

ducted in order to reduce the consumption of raw materials, that

is, nanocomposite microspheres. As shown in Fig. 45.3b, a minia-

ture sintering platform was designed and installed in the build part

of the Sinterstation

R

2000 SLS machine.

54

The miniature sintering

platformconsistedprimarilyofaminiaturebuildpartandtwopow-

der tanks similar to those of the commercial SLS machine but with

much reduced sizes. The movement of the miniature build part was

synchronized with the existing build part of Sinterstation

R

2000

machine, and the two miniature powder tanks were driven by two

additional stepping motors fixed within the miniature platform. In

the sintering processes, small amounts of microspheres were fed

into the miniature powder tanks with the original powder tanks

being kept empty. Two sensors were installed to sense the roller

positions, and the signals were fed back to a control panel, which

could control the movement of miniature powder tanks. This mod-

ified SLS system only requires small amounts of particulate raw

materials for scaffold fabrication and can sinter good-quality scaf-

folds in an effective and e

cient manner. Similarly, for the same

Search WWH ::

Custom Search