Biomedical Engineering Reference

In-Depth Information

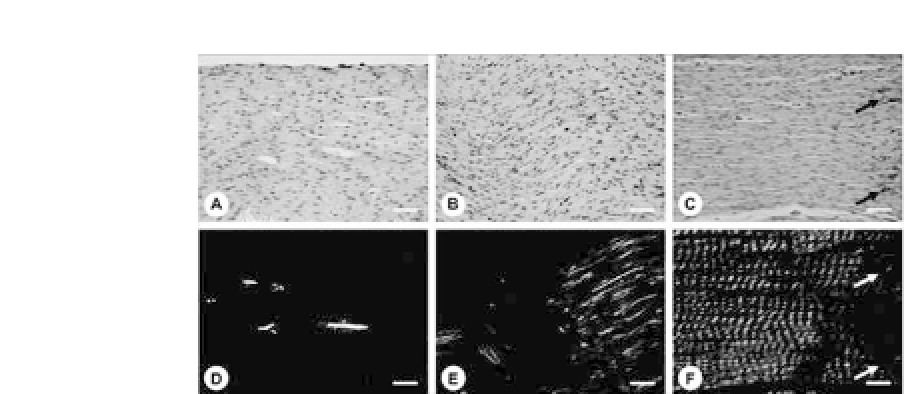

Figure 34.5.

H&Estaining(a-c)andpolarizedmicroscopicviews(d-f)of

in vitro

-engineered tendon after total 12 weeks (a and d) and of

in vivo

-

implanted tendons for 14 weeks without (b and e) and with (c and f) load-

ing.Originalmagnifications:

200;barrepresents50

μ

mforall.(Reprinted

by permission from Ref. 13). See also ColorInsert.

×

collagen fibers, a more mature collagen fibril structure with D-band

periodicity, and stronger mechanical properties (Fig. 34.5).

These results indicate that

in vivo

mechanical loading via an

ex

vivo

approach might be an optimal approach for engineering func-

tionaltendontissue.Therefore,areasonablestrategyforengineered

functional repair of tendon defects might be to generate a neo-

tendon tissue first

in vitro

and then to implant

in vivo

for its further

maturation and for carrying out itsfunctions.

Thephysicalformofpolymerfibersmayalsoaffecttheirmechan-

icalpropertyandlikelytheirdegradationrate.Apreviousstudyper-

formed in our center found that once in a woven fashion, PGA fibers

could significantly enhance their mechanical strength. Additionally,

the woven fibers also seemed to degrade more slowly compared

withnonwovenfibersat the same time points.

14

34.3 PGA Scaffold for Cartilage Engineering

Cartilage engineering is another major area of tissue construc-

tion. Engineering of hyaline cartilage to repair large, full-thickness

defects of articular cartilage became the first target because the

defect remains to be a major concern in clinical practice due to the

lack of proper therapy.

15

In a porcine model, autologous articular

Search WWH ::

Custom Search