Biomedical Engineering Reference

In-Depth Information

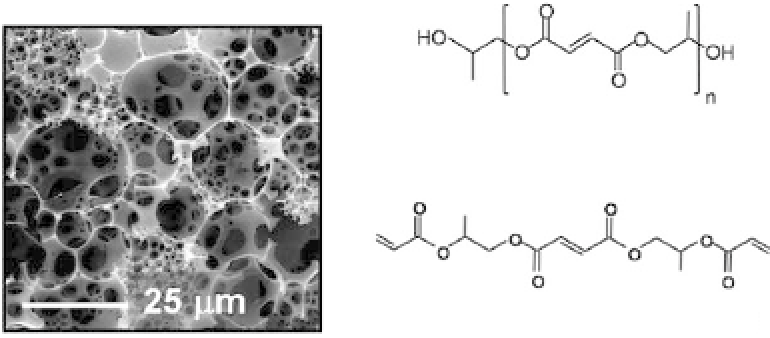

Poly(Propylene Fumarate) (PPF)

Propylene Fumarate Diacrylate (PFDA)

Figure 33.7.

SEM image of fumarate-based polyHIPEs fabricated from

PPF and PFDA. Reprinted with permission from Ref. 37; copyright 2007

American Chemical Society.

addition of a vinyl-based comonomer such as styrene. This resulted

in the first fully biodegradable polyHIPE scaffold.

33.5 New Synthesis Routes

Vinyl monomers copolymerized with a divinyl cross-linker are the

most commonly used systems to generate polyHIPEs.

23

,

36

,

46

,

55

The

resulting monoliths are rigid and relatively brittle. In contrast,

Lepine

et al

. reported the first preparation of polyHIPEs based

on a polyurethane network.

56

This strategy was used to enhance

the elasticity and toughness of the monoliths. Scaffolds of a pure

polyurethane network were found to be too soft and underwent

a high level of shrinkage. The addition of styrene and divinyl-

benzene resulted in the generation of rigid, microcellular IPNs. A

difunctional comonomer, hydroxybutyl methacrylate, was then uti-

lized to create covalent links between the two networks of the IPNs.

As expected, the incorporation of a high concentration (40%) of a

polyurethane (PU) elastomer into the PS rigid network decreased

the modulus and increased the flexibility of the polyHIPE. How-

ever, a lower concentrations (20%) of PU resulted in monoliths

with an increased modulus as compared to the PS network. The

authors hypothesized that this effect was due to an increase in

the proportion of cross-links, which was supported by a threefold

Search WWH ::

Custom Search