Biomedical Engineering Reference

In-Depth Information

required functionality can be an easy solution. In this case, matrices

areengineeredintodifferentsegmentsorlayersbyclearboundaries

accordingtotheirrole.Forinstance,thesourcewillbeencapsulated

at the core and then coated with another layer having the activating

catalyst.Suchdesignallowsthegenerationofoxygeninacontrolled

manner during application, while the loss of the source will be min-

imized during production as the activating agent is not in contact

directly with the source. Materials chosen for each segment may be

of different types but must be able to attach together boundary to

boundary, while being ready to be grafted with the required func-

tionality.

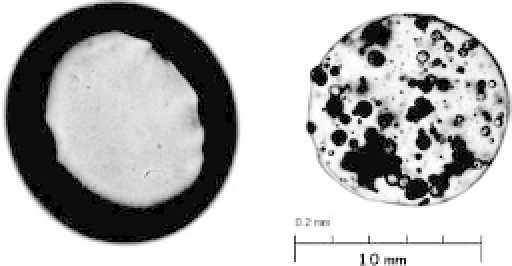

A successful attempt has been demonstrated in mixing PLGA

microspheres encapsulated with H

2

O

2

into alginate beads, in which

the alginate was first grafted with catalase. Alginate is chosen as the

second coating layer as its backbones consist of a carboxylic group

that is suitable to be grafted with catalase, besides showing no toxic

effect, being biocompatible, and being well employed in encapsu-

lated bioreagents.

58

,

59

In addition, an alginate solution can be easily

formedintoahydrogelusingadivalentcationsuchasbarium(II)or

calcium (II) ions. PLGA microspheres, although from different kinds

of materials, were found to be evenly distributed within the algi-

natebead,asobservedclearlyfromtheimagetakenunderanoptical

microscope (Fig. 32.1).

Figure 32.1.

H

2

O

2

-encapsulated PLGA microspheres that are evenly dis-

tributed within an alginate matrix that has been grafted with catalase

to decompose the H

2

O

2

. Black spots in the right bead were the PLGA

microspheres, while the alginate hydrogel was transparent under the opti-

cal microscope. The left microbead is the control, produced using alginate

without the additionof PLGAmicrospheres.

Search WWH ::

Custom Search