Biomedical Engineering Reference

In-Depth Information

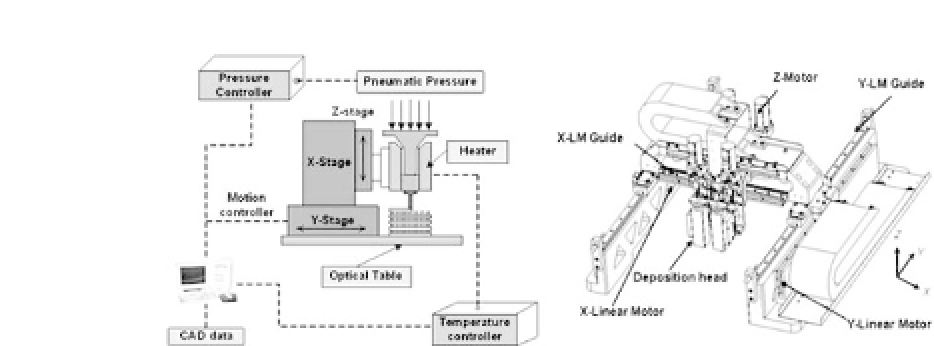

Figure 31.11.

(a) Schematic diagram of the developed MHDS and (b)

image of the designed and manufactured MHDS.

designedmicroscalefeatures.ThetypicalporesizeoffabricatedPCL

scaffold ranges from 200 to 300

μ

m, which is near the optimal size

suggested for bone tissue scaffold applications. The compressive

modulus of scaffolds ranges from 150 to 200 MPa. The preliminary

results of biological experiments demonstrate the biocompatibility

of the PEDprocess and PCL materials.

Kim

et al

.

26

,

34

described the adhesion of human BMSCs and

the proliferation characteristics of various scaffolds that consist of

biodegradablematerialsandthatwerefabricatedusingamultihead

deposition system (MHDS) developed by the authors (Fig. 31.11).

The MHDS may be superior to other commercialized systems using

theFDMprocessinthatitcanconvenientlyandquicklyfabricatevar-

ioushybridscaffolds.TheMHDSenablesthefabricationof3Dtissue

scaffolds with a resolution of several tens of microns (Fig. 31.12). In

addition, multideposition heads installed in the MHDS permit rapid

fabrication and manufacture of blended scaffolds with various bio-

material compositions. PCL, PLGA, blended PCL/PLGA, and blended

PCL/PLGA/TCP scaffolds, which had the same inner/outer archi-

tecture, were manufactured adequately and had perfectly intercon-

nected pores. The mechanical testing and cell proliferation results

show that the blended PCL/PLGA/TCP scaffold was superior to

other scaffolds. The feasibility of this application to tissue engineer-

ingofSFF-based3DscaffoldsfabricatedusingMHDSwasconfirmed

throughscaffoldfabrication,mechanicaltesting,andcellinteraction

evaluation.

Search WWH ::

Custom Search