Biomedical Engineering Reference

In-Depth Information

(a)

(b)

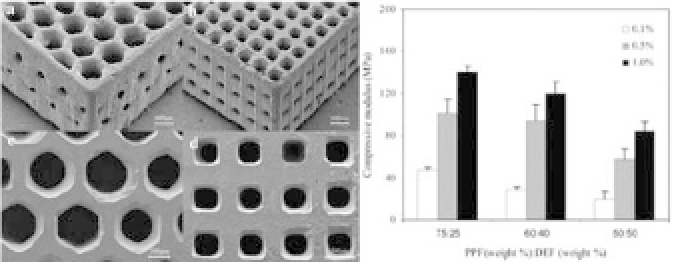

Figure 31.3.

(a) Fabricated scaffolds using PPF/DEF resin and (b) com-

pressive modulusof a cylindrical sample of PPF/DEFresin.

11

TMC, which can be cross-linked by ring-opening polymerization,

becomes a TMC-based photopolymer via combination with initia-

tors such as trimethylolpropane (TMP),

ε

-caprolactone (CL), or var-

ious molecular weights of polyethylene glycol (PEG). Kwon

et al

.

fabricated two-dimensional (2D) patterns and 3D structures with

TMC/TMP and TMC/PEG and observed the effects of the materials

on cell adhesion and proliferation (Fig. 31.4).

12

Further Lee

et al

.

fabricated a 3D scaffold with TMC/TMP using the MSTL system and

applied the scaffoldin cartilage regeneration (Fig. 31.5).

13

Schuster

et al

. developed an acrylate-based monomer formu-

lation consisting of a biodegradable-basis monomer derived from

gelation hydrolysate. These studies demonstrated that a 3D shape

could be fabricated using this material. In addition, they mixed

various reactive diluents such as urethanedimethacrylate (UDMA),

diisobutylacrylamide (DBA), dipentaerythritol pentaacrylate (PPA),

pentaerythritol triacrylate (PTA), trimethylolpropane triacrylate

Figure 31.4.

SEM image of (a) micropillar array, (b) microcorn array, and

(c) microbank array from TMC/PEG200.

12

Search WWH ::

Custom Search