Biomedical Engineering Reference

In-Depth Information

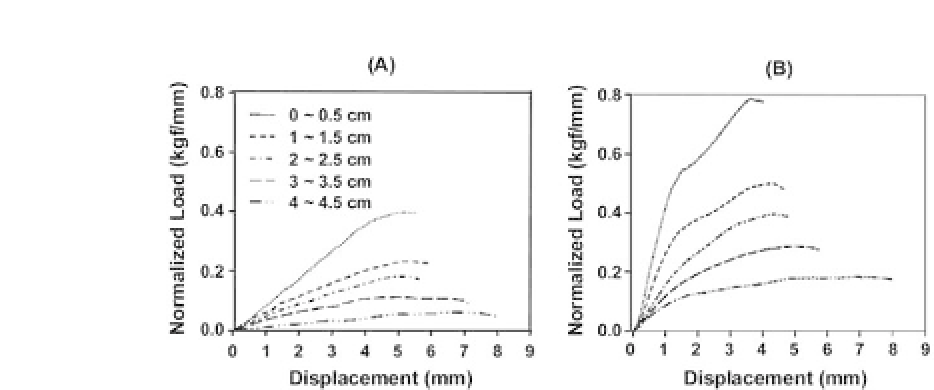

Figure 30.6.

Normalized load displacement curves of cylindrical alginate

scaffold sections along the longitudinal direction. (a) Nontreated and (b)

chitosan-treated scaffold sections (Ref. 22).

specimen placed on a mold-type grip, and the load displacement

curves were obtained. The load values were normalized by divid-

ingwiththethicknessofscaffold(load/scaffoldthickness,kg

f

/mm).

Figure 30.6 compares the mechanical strengths of alginate scaffold

sections with/without chitosan treatment. The mechanical strength

of the scaffold sections along the longitudinal direction gradually

decreased with increasing pore size and porosity, as expected (bot-

tom positions of the cylindrical scaffold have smaller pore sizes

as well as lower porosities, as discussed earlier). The chitosan-

treatedscaffoldsections(Fig.30.6b)showeddramaticallyincreased

mechanical strengths compared with the scaffold sections without

the treatment (Fig. 30.6a).

It seemed that the positively charged chitosan provides the ion

complex with the negatively charged alginate fibrils (i.e., ion com-

plex between -NH

3

+

of chitosan and -COO

-

of alginate), resulting

in the fibril bonding and the increased mechanical strengths. The

chitosan treatment to alginate scaffolds may provide an additional

benefit of improving cell compatibility. The mechanical strengths of

chitosan scaffolds showed a similar trend to the alginate scaffold:

the mechanical strength of the scaffold sections along the longitudi-

nal direction gradually decreased with the increasing pore size and

porosity (Fig. 30.7), but the strengths were lower than the alginate

scaffold sections even though their pore sizes and porosities were

almost the same.

Search WWH ::

Custom Search