Biomedical Engineering Reference

In-Depth Information

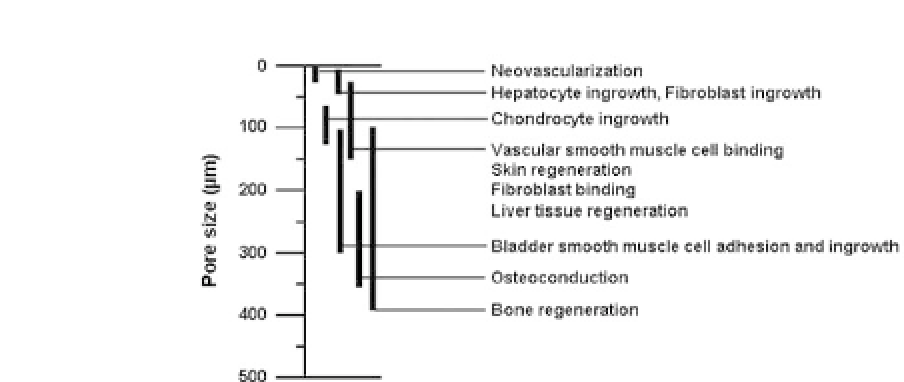

Figure 30.1.

Suggested optimum pore size ranges for different cells or

tissues (Ref. 22).

bladdersmoothmusclecelladhesionandingrowth,

17

100

∼

400

μ

m

forboneregeneration,

18

-

21

and200

mforosteoconduction

8

(summarizedinFig.30.1),dependingoftheporosityaswellasscaf-

fold materials used. Nevertheless of these investigations, more sys-

tematicevaluationonoptimumporesizerangesofscaffoldhasbeen

stillrequiredbecauseoftheabsenceofwell-definedscaffoldswitha

wide range of pore sizes. Thus, if the scaffold with a pore size gradi-

ent can be prepared, it will become a powerful tool for basic stud-

ies of the interactions between cells or tissues and scaffolds with

different pore sizes since the effect of pore size can be effectively

examined using one scaffold. Several techniques, including partic-

ulate leaching, phase separation, freeze-drying, gas foaming, fiber

bonding, and 3D printing have been used to fabricate porous poly-

mer scaffolds having a 3D pore structure.

1

Among them, the par-

ticulate leaching and freeze-drying methods, which can control the

pore size of scaffolds by porogen size and freezing temperature,

respectively,havebeencommonlychosentoevaluateoftheporesize

effect.

18

,

23

However, it is not possible from those techniques to fab-

ricate scaffolds with a pore size gradient. Also it is troublesome that

the scaffolds with different pore sizes are separately fabricated, and

thus low reproducibility of pore size distribution is still a limitation.

Recently,3Dprinting

24

andspinning

25

techniqueshavebeentriedto

fabricate scaffolds witha pore sizegradient.

∼

350

μ

Search WWH ::

Custom Search