Biomedical Engineering Reference

In-Depth Information

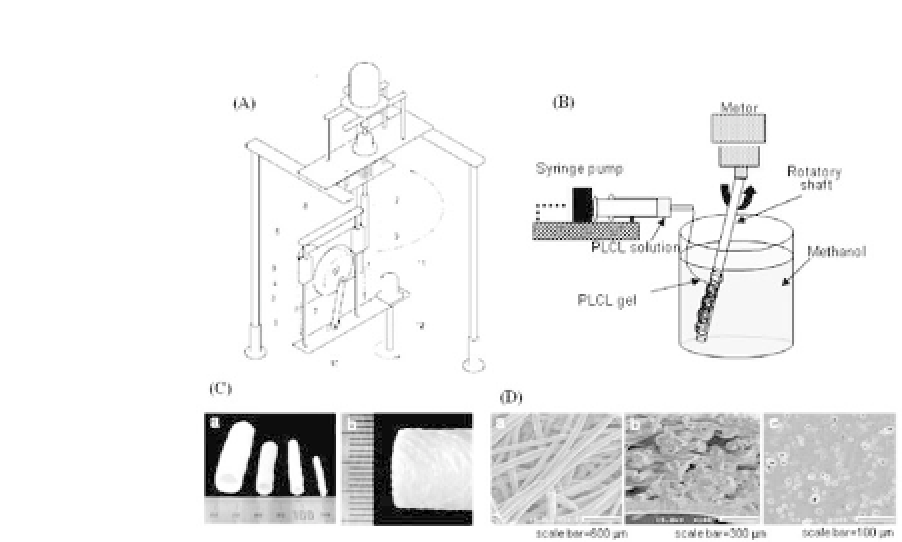

Figure 27.3.

Device (A) for gel-spinning molding technique (B) and

appearance(C)oftubularfibrousPLCLscaffoldspreparedbythetechnique.

SEM images of a double-layered PLCL scaffold (D, a: outer surface, b: cross-

section, and c: luminal surface).

blood vessels, such as the aorta, rather than for use in

in vitro

culture for tissue reconstruction.

22

FibrousPLCLscaffoldswere

enforced with a microporous inner layer for blocking of blood

leakage during implantation due to the large pore space on

the interior of nonreinforced PLCL scaffolds. Cylindrical shafts

were dip-coated with a PLCL/salt mixture and coupled to a gel-

spinning molding device for the formation of the outer fibrous

structure. The morphology of double-layered scaffold is shown

in (Fig. 27.3D). The individual fibers of the outer layer were

found to be crossed and/or fused together with neighboring

fibers (Fig. 27.3D-b). These cross-linked fibrous networks cause

the spun PLCL scaffolds to be open-pore structures and well-

interconnected between pores (Fig. 27.3D-a). An inner layer (Fig.

27.3D-c), which was a membrane with separated pores, was shown

to be well fused with the outer fibrous networks (Fig. 27.3D-b).

The scaffolds exhibited 550-670% elongation-at-break. The elas-

tic features of the scaffolds are shown in (Fig. 27.4A). The scaf-

folds exhibited a complete rubber-like elasticity being recovered

Search WWH ::

Custom Search