Biomedical Engineering Reference

In-Depth Information

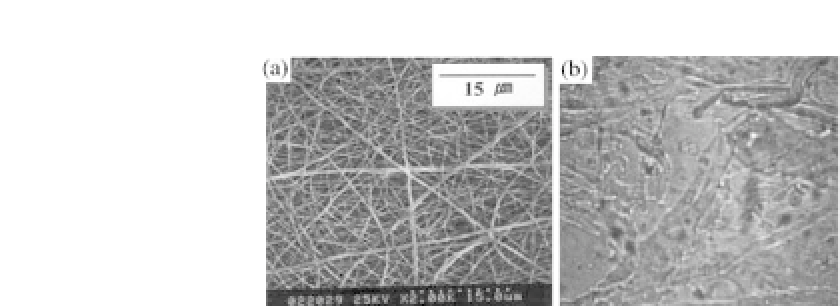

Figure 12.4.

PU wound dressings: (a) representative SEM image of

PU wound dressing prepared by electrospinning; (b) photograph of

Tegaderm

TM

(

×

200). Reprinted from Ref. 14 with permission from John

Wiley & SonsInc.

polymers have been explored for skin tissue engineering; however,

the use of these biomaterials as nanofibers has been very lim-

ited. Recently, researcher developed silk fibroin nanofiber matri-

ces by electrospinning for skin tissue engineering.

17

Due to

their high porosity and high surface-area-to-volume ratio, fibroin

nanofibers coated with type I collagen were found to promote ker-

atinocyte/fibroblast adhesion and spreading. Therefore, silk fibroin

nanofibers show potential to be developed as a scaffold for skin

tissue engineering. Khil

et al.

14

,

18

studied polyurethane (PU) elec-

trospun nanofiber matrices for the purpose of wound dressings

(Figs. 12.4 and12.5).

PU nanofiber matrices provided excellent oxygen permeability

and controlled water evaporation. By virtue of these properties, the

matrices allowed fluid from the wound to exude, while prevent-

ing dehydration of the wound. Further, the ultrafine porosity of the

matrices disallowed invasion by exogenous microorganisms. These

results indicated that PU nanofiber matrices showed potential to be

developed as wound-dressingmaterials.

12.3.2

Blood Vessel (Vascular and Cardiac) Grafts

Vascular grafts are in large demand for coronary and peripheral

bypass surgeries. Although synthetic grafts have been developed,

replacement of vessels with purely synthetic polymeric conduits

often leads to the failure of such grafts, especially in grafts less than

Search WWH ::

Custom Search