Biomedical Engineering Reference

In-Depth Information

vapor, it should be reactive with toxic gases and chemicals, it should

be insoluble in solvents, and it should be lightweight. As discussed

before, due to the very small pore size of nanofiber matrices, they

provide an impermeable barrier to toxic chemical agents. Also the

high surface-area-to-volume ratio of nanofibers enables them to

formlightweightfabricswithremarkablebreathingproperties.

4

Due

to the simplicity and versatility of the electrospinning process, con-

ductive fibers can be fabricated from polymers with unusual elec-

trical, electronic, ionic, photoelectric, and piezoelectric properties.

Thesefiberscouldbeusedinthefabricationofnovelnanoelectronic

devices, nanoelectronic machines, and sensors for high-technology

applications.

6

In electrospinning, polymer solutions are deposited as fibrous

matrices, in which chain entanglements in a su

ciently high-

polymer concentration in solution produce continuous fibers.

7

Although the process of electrospinning has been known for some

time,

8

and attempts have been made previously to make vascular

grafts using this technique,

9

the application of electrospun fibers as

scaffolds for tissue engineering has recently investigated by many

researchers.

3

,

5

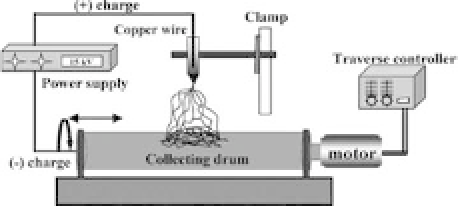

The prototype electrospinning setup that has been

employedinthisstudyisillustratedschematicallyinFig.12.1,which

consistsofasyringe,agroundelectrode(aluminumsheetonarotat-

ing drum) 10-15 cm from the needle, and a high-voltage power

supply. Jet initiation is achieved by charging the polymer solution,

followedbyinjectionthroughthecapillarytipwithatipdiameterof

0.5 mm. Because of its charge, the ejected solution is drawn toward

the collector as a whipping jet.

10

During the jet's travel, the solvent

Figure 12.1.

A schematic of electrospinning. Reprinted from Ref. 10 with

permission from Elsevier.

Search WWH ::

Custom Search