Biomedical Engineering Reference

In-Depth Information

10.2 Electrospinning Technology

Electrospinning has been widely used as a fabrication method to

generatenanofibersforvarioustissueengineeringapplications.The

nano-scaled fiber structures generated by this method are designed

to support cell adhesion and guide cellular behavior. This technol-

ogy offers the ability to control scaffold composition, structure, and

mechanical properties.

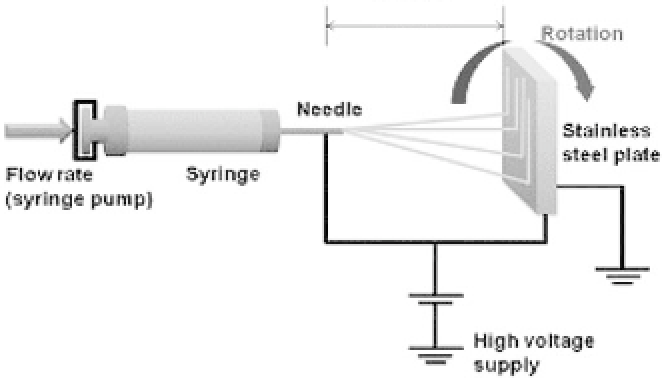

Electrospinning requires a high-voltage power supply, a syringe

pump,apolymersolutiontobespun,andagroundedcollectionsur-

face. Solutions containing various materials are exposed to a high-

voltage power supply at 5-25 kV potential between the solution tip

andthegroundedsurface(Fig.10.1).Thesolutionisdeliveredwitha

syringethroughablunt-tipneedleataflowrateof3-10mL/hrusing

a syringe pump. Fibers can be collected onto a specially designed

groundedmandrelatadistanceof5-30cmfromtheneedletip.Con-

trolling certain variables during electrospinning allows for control-

ling morphology,diameter, and alignmentof fibers

6

(Table 10.1).

The fabricated electrospun nanofibers possess unique features

and properties, including an extremely high surface-area-to-volume

ratio,whichallowsforenhancedcellularinteractionswithscaffolds.

Distance

Needle

Stainless

steel plate

Syringe

Flow rate

(syringe pump)

High voltage

supply

Figure 10.1.

Electrospinning methodology. Fibers are collected on a

grounded surface. The electrostatic field causes splaying of solution, and

solutions of su

cient viscosity and surface tension form fibrous mats that

adhere to the grounded surface.

Search WWH ::

Custom Search