Biomedical Engineering Reference

In-Depth Information

Table 3.3 Second generation highly crosslinked UHMWPEs

Tradename

Manufacturer Radiation Post-irradiation

Sterilization

dose

treatment

method

(kGy)

E-Poly (E1)

TM

Biomet

100

Vitamin E diffusion

Gamma

irradiation

X3

TM

Stryker

90

Sequential annealing

Gas plasma

(330)

ArComXL

TM

Biomet

50

Mechanical deformation Gas plasma

crosslinking, the other is the diffusion of the antioxidant into radiation cross-

linked UHMWPE. In addition to protecting UHMWPE against oxidation

initiated by radiation-induced free radicals (Oral et al., 2004, 2006c), vitamin E

reacts with primary free radicals induced on the polymer chains during radiation

and prevents crosslinking with increasing concentration (Parth et al., 2002; Oral

et al., 2005). In fact, crosslink density reaches a saturation level and at a vitamin

E concentration of 0.3 wt% (3000 ppm) or above, it is not possible to crosslink

UHMWPE to a level equivalent to that of 100 kGy irradiated virgin UHMWPE

(Oral et al., 2008). Therefore, if blending followed by radiation crosslinking is to

be used, the antioxidant concentration and the radiation dose have to be carefully

optimized to obtain good wear resistance and enough vitamin E to protect the

UHMWPE against oxidation in the long term. The vitamin E-containing

UHMWPE currently in clinical use (introduced in hips in 2007 and in knees in

2008) is prepared by post-irradiation diffusion of vitamin E using a two-step

doping and homogenization process to ensure the penetration of vitamin E

throughout the entire thickness of components (Oral et al., 2007). This material

has a uniform vitamin E concentration profile.

Vitamin E-stabilized, highly crosslinked UHMWPE has about 35% more

fatigue resistance than irradiated and melted UHMWPE due to the elimination

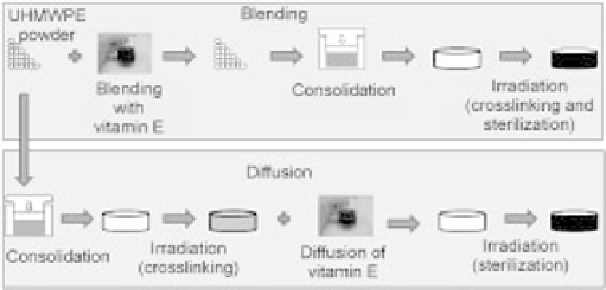

3.6 Vitamin E incorporation methods in highly crosslinked UHMWPE.