Biomedical Engineering Reference

In-Depth Information

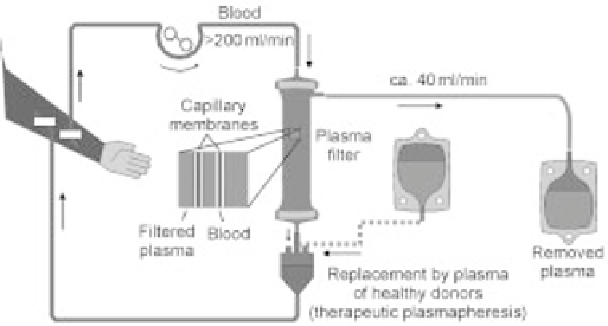

1.9 Principle of membrane plasma separation.

For plasma separation, the blood plasma is separated from the cells by either

centrifugation or membrane filtration (Fig. 1.9). The pore size of the separation

membranes is in the range of less than 0.5m, thus small enough to hold back

the smallest blood cells: platelets.

Blood plasma is pumped through a filter very similar to a dialyser and plasma

migrates through the pores driven by an excess pressure on the blood side. This

excess pressure can be achieved by a pump or through gravity. The plasma can

then be discarded and replaced by saline or protein solutions or treated further.

The consecutive steps can be additional filtration steps as in cascade filtration or

adsorption processes. The blood cells are dispersed in saline or a protein solution

and returned to the patient.

1.3.2 Manufacture and resulting structure

Hydrophobic synthetic membranes

The production of hydrophobic synthetic plasma separation membranes is done

through a TIPS process and is very similar to that of blood oxygenation

membranes (see pages 10±12): the basic polymer (PE or PP) is dissolved in a hot

mixture of solvents. This solution is forced through a ring-shaped spinneret. After

exiting the spinneret, the solution is cooled, so that the polymer recrystallises.

The solvent aggregates to droplets, which are trapped in the polymer matrix.

After extraction of the solvent, the space where the solvent has been constitutes

the pores. These pores need to be larger than those for the blood oxygenation

membranes to allow a sufficient transport of plasma through the membrane wall.

The structure of these membranes consequently is very similar to that of

TIPS-produced blood oxygenation membranes (Fig. 1.10). The membrane has a

homogeneous, sponge-like structure with a constant pore size throughout the

whole membrane wall.