Biomedical Engineering Reference

In-Depth Information

1.4 Dry stretch process for manufacture of hollow fibre blood oxygenation

membranes.

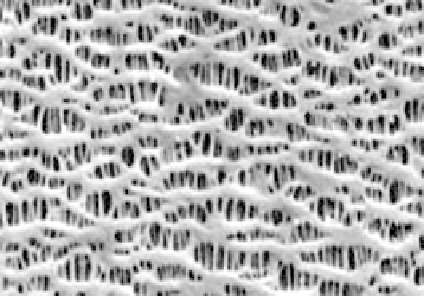

By this annealing and stretching process, the tight capillary wall is ruptured to

build pores. Of course the properties of the raw capillary and the conditions of

the various stretching and annealing steps need to be adjusted very carefully to

yield pores of the desired shape and in the target range of pore size. In the

scanning electron micrographs (SEMs) in Fig. 1.5 the direction of the stretching

process is in the vertical direction: the pores exhibit a lengthy shape into the

direction of the stretch.

This process yields a membrane that has good mechanical stability and is

ideal for demanding textile make-up such as winding at elevated speed. By

adjusting the temperatures and forces, the pores can be generated in a way that

means plasma breakthrough is not an issue.

The same technology can of course also be applied to films of PP, so that flat

sheet membranes can be produced according to the same scheme. Such mem-

1.5 SEM of oxygenation membranes produced by dry stretch.