Geology Reference

In-Depth Information

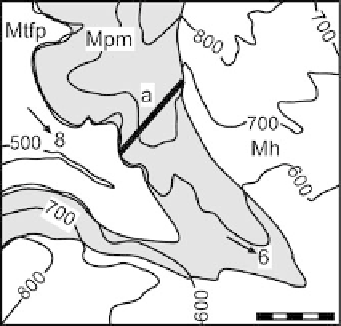

Fig. 4.7.

Line of a thickness measure-

ment (

a

) on a geologic map

on a topographic base

4.1.4

Effect of Measurement and Mapping Errors

In the determination of thickness from measurements on a map, there are three sources

of error, the length and the direction measurements, the dip measurement, and the

contact locations. Errors in length will result from the finite widths of the contact

lines at the scale of the map. The minimum possible length error is approximately

equal to the thickness of the geologic contacts as drawn on the map. For example, the

geologic contacts in Fig. 4.7 are about 20 ft wide. Thus a thickness error of about

±20 ft is about the best that could be done on this map. Small errors in contact loca-

tions may lead to large errors in the calculated thickness, depending on the measure-

ment direction. Uncertainties in the dip amount and dip direction of a degree or two

are to be expected. The effects of error in the dip range from very small if the thick-

ness measurement is at a high angle to the bed boundary, to very large if the mea-

surement is at a low angle to the boundary.

The effect of errors in bedding attitude and measurement direction on a thickness

determination can be estimated using Eq. 4.1 which places the variables in their sim-

plest form. The true thickness (

t

) is directly proportional to the apparent thickness (

L

)

and so the erroneous thickness (

t

e

) is directly proportional to the error in the length

of the apparent thickness measurement. The error measure (

t

e

) is normalized in Fig. 4.8

to remove the effect of the length scale. The true thickness in Eq. 4.1 is proportional

to the cosine of the angle between the pole to the bed and the line of the thickness

measurement (

), leading to a non-linear dependence of the error on the size of the

angle (Fig. 4.8). The angle error could be in the orientation of the bed, in the orienta-

tion of the apparent thickness, or a combination of both. A combined error in

ρ

of ±5°

from the correct value seems like the upper limit for careful field or well measure-

ments. An angle of

ρ

= 0° means that the thickness measurement is perpendicular to

bedding; this is the most accurate measurement direction. An angle of

ρ

= 90° means

that the measurement direction is parallel to bedding, an impossibility. The sensitivity

of a thickness measurement to error in the angle goes up rapidly as

ρ

increases (Fig. 4.8).

The thickness error exceeds ±10% at an angle of 40° and is about 100% at 80 + 5° and

ρ